Uncategorized

MVTec HALCON 25.11 crack license unlocked

MVTec HALCON 25.11: Advancing Machine Vision with Speed and Intelligence

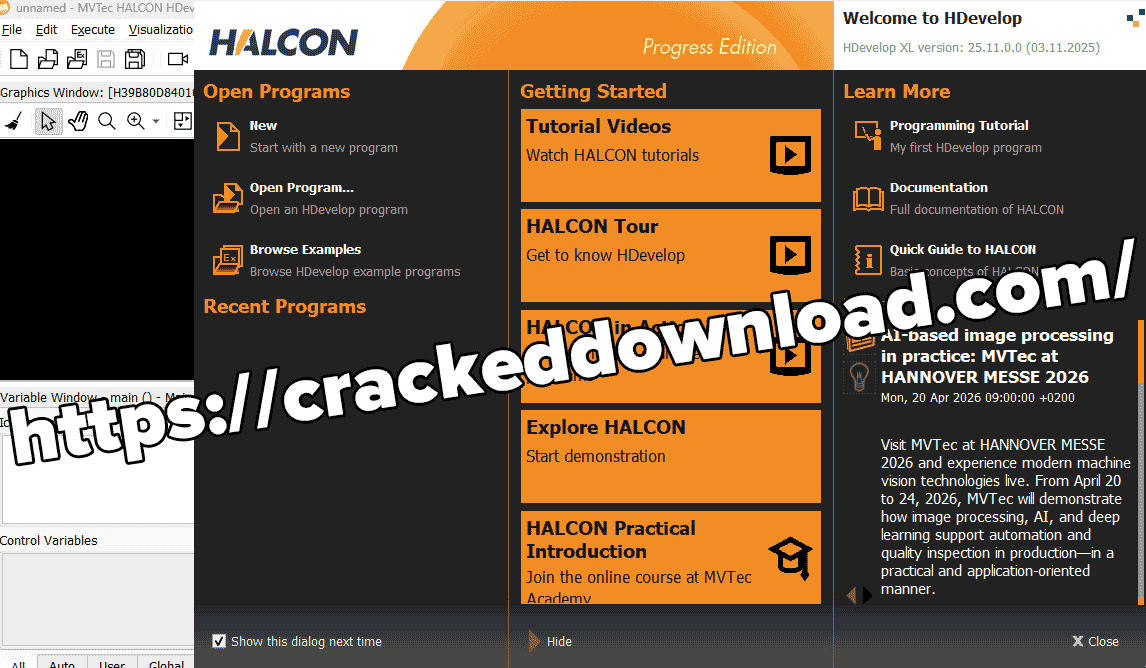

MVTec HALCON 25.11 represents a significant milestone in machine vision software development, released by MVTec Software GmbH on November 12, 2025. This latest version builds upon HALCON’s established reputation as a comprehensive standard software for machine vision, introducing enhanced capabilities that address the growing demands of industrial automation, quality control, and intelligent manufacturing.

HALCON 25.11 download MVTec HALCON 25.11

Introduction to HALCON 25.11

HALCON 25.11 download MVTec HALCON 25.11

As industries worldwide embrace digital transformation and smart manufacturing, the need for fast, reliable, and adaptable machine vision systems has never been greater. HALCON 25.11 rises to meet these challenges with a clear focus: speed. This release delivers substantial performance improvements across deep learning applications, enabling real-time decision-making even on resource-constrained embedded devices.

“Speed is a crucial factor in ensuring that deep-learning-based applications can be used profitably in practice. For the new HALCON version, we have optimized the deep learning models for classification and code reading. As a result, inference is accelerated many times over,” explains Jan Gärtner, Product Manager HALCON at MVTec.

Revolutionary Deep Learning: Continual Learning for Classification

The Challenge of Adaptation

Production environments are dynamic. Changes in lighting conditions, material variations, new product lines, and evolving quality standards all demand that machine vision systems adapt quickly. Traditionally, retraining deep learning models has been a complex, time-consuming process that requires extensive datasets and significant computational resources. Worse, the phenomenon of “catastrophic forgetting”—where models lose their ability to recognize previously learned patterns when trained on new data—has posed a persistent challenge.

The Solution: Continual Learning

HALCON 25.11 introduces Continual Learning, a groundbreaking feature that fundamentally changes how classification models are trained and maintained. This innovative technology enables users to:

- Add new classes quickly without starting from scratch

- Incorporate new image data for retraining with minimal effort

- Avoid catastrophic forgetting through intelligent model architecture

- Reduce training time dramatically, requiring only a few images

- Lower costs associated with model adaptation and maintenance

“When certain parameters in production change, deep learning-based machine vision applications must be retrained to maintain robust recognition rates. So far, this process has been complex and time-consuming. With Continual Learning in HALCON 25.11, we now offer a feature that significantly reduces the effort required to retrain classification models,” states Jan Gärtner.

This feature is particularly valuable in industries where product variations are frequent, quality standards evolve, or production conditions change regularly. Manufacturing facilities can now maintain high recognition accuracy without the downtime and expense traditionally associated with model retraining.

Optimized Deep OCR Models: Speed Meets Accuracy

Performance Breakthrough

Text reading and optical character recognition (OCR) are critical functions in modern manufacturing, from serial number verification to label inspection and lot tracking. HALCON 25.11 introduces optimized Deep OCR recognition models that achieve a remarkable performance milestone: up to 50× faster inference on embedded devices compared to previous versions.

Key Advantages

Speed without Compromise: These new models deliver dramatic speed improvements while maintaining accuracy levels. This combination is essential for high-throughput production lines where every millisecond counts.

Resource Efficiency: Designed specifically for embedded devices, the optimized models enable powerful OCR capabilities on low-power hardware. This opens up new possibilities for deploying machine vision in space-constrained and power-limited environments.

Industrial-Ready: The models come pretrained on industrial data and include proven alignment preprocessing techniques. This means they’re ready to tackle real-world challenges right out of the box, including:

- Serial number inspection: Verifying product authenticity and traceability

- Label verification: Ensuring correct labeling and compliance

- Lot tracking: Managing inventory and quality control across production batches

- Expiration date reading: Monitoring product freshness and regulatory compliance

- Barcode and code reading: Rapid identification and data capture

Real-Time OCR on the Edge

The ability to perform real-time OCR on embedded devices represents a significant advancement for the industry. Previously, achieving fast OCR often required powerful desktop computers or specialized hardware. With HALCON 25.11, manufacturers can deploy sophisticated text reading capabilities directly on production lines using cost-effective embedded systems.

Score Visualization for Shape Matching

Enhanced Developer Experience

Responding to valuable customer feedback, HALCON 25.11 includes improved visualization capabilities for matching methods. The enhanced Score Visualization feature provides developers and engineers with clearer insights into shape matching performance.

Visual Clarity

The new visualization displays:

- Detected edges in one color, showing successful matches

- Undetected edges in a different color, highlighting areas of concern

- Clear differentiation that makes troubleshooting faster and more intuitive

This improvement streamlines the development and debugging process, enabling engineers to quickly identify why certain matches succeed or fail. The ability to visualize matching performance at a glance reduces development time and improves application reliability.

Extended Functionality

The technical implementation extends several HALCON operators:

get_generic_shape_model_resultnow retrieves contour informationget_generic_shape_model_paramincludes the ‘score_visualization_enabled’ parameter- New example code demonstrates practical implementation

MobileNetV4 Classification Models

HALCON 25.11 integrates MobileNetV4, the latest generation of efficient neural network architectures designed for mobile and embedded vision applications. MobileNetV4 represents state-of-the-art performance in classification tasks while maintaining the efficiency necessary for deployment on resource-constrained devices.

This addition expands the toolkit available to machine vision developers, offering:

- Improved accuracy on classification tasks

- Efficient architecture optimized for embedded systems

- Versatility across various industrial applications

- Future-proof technology aligned with the latest deep learning research

Comprehensive Feature Set

Beyond the headline features, HALCON 25.11 includes numerous improvements and refinements across the platform. As with every semiannual release, MVTec has incorporated customer feedback and integrated corresponding requests into HALCON, ensuring the software evolves in alignment with real-world user needs.

Industry Applications and Use Cases

Manufacturing and Quality Control

HALCON 25.11’s enhanced capabilities make it ideal for diverse manufacturing scenarios:

- Automotive: Component inspection, assembly verification, defect detection

- Electronics: PCB inspection, chip placement verification, solder joint analysis

- Pharmaceuticals: Label verification, packaging inspection, pill counting

- Food and Beverage: Quality control, packaging inspection, best-before date verification

- Consumer Goods: Product authentication, packaging integrity, barcode reading

High-Throughput Production Lines

The speed optimizations in HALCON 25.11 are particularly valuable in high-throughput environments where every product must be inspected in real-time. The software’s ability to deliver fast inference on embedded devices means that manufacturers can deploy multiple inspection points without incurring the cost and complexity of high-end computing infrastructure at each location.

Flexible Production Environments

The Continual Learning feature shines in flexible manufacturing settings where product variations are common. Facilities producing customized products, seasonal variations, or frequently introducing new items can now adapt their machine vision systems quickly and cost-effectively.

Edge Deployment

With optimized models that run efficiently on embedded devices, HALCON 25.11 enables true edge computing for machine vision. This approach offers several advantages:

- Reduced latency: Processing happens locally, eliminating network delays

- Lower bandwidth requirements: No need to stream images to central servers

- Enhanced reliability: Systems continue operating even if network connectivity is lost

- Improved privacy: Sensitive production data stays on local devices

- Cost efficiency: Reduced infrastructure requirements and operating costs

Technical Architecture and Integration

Software Manager (SOM)

HALCON 25.11 can be easily downloaded and installed using the MVTec Software Manager (SOM), which provides a streamlined online installation experience. For environments without internet access, MVTec also provides offline installers.

Documentation and Support

MVTec provides comprehensive documentation for HALCON 25.11, including:

- Complete API reference

- Release notes detailing all changes

- Example code demonstrating new features

- HDevelop example programs

- Installation guides and troubleshooting resources

Compatibility and Licensing

Following MVTec’s release strategy, HALCON 25.11 is available as a “Progress” release, representing the latest features and capabilities. The software maintains compatibility with existing HALCON applications while introducing new functionality that developers can adopt as needed.

The MVTec Development Philosophy

Semiannual Release Cycle

MVTec follows a consistent semiannual release schedule, delivering new HALCON versions in May and November each year. This predictable cadence provides several benefits:

- Regular innovation: Users receive new features and improvements consistently

- Manageable updates: The six-month cycle allows time for testing and integration

- Continuous feedback loop: Customer input informs each new release

- Stable foundation: Core functionality remains reliable while new features are added

Customer-Driven Development

A hallmark of HALCON’s evolution is MVTec’s commitment to incorporating customer feedback. The Score Visualization feature in version 25.11 exemplifies this approach—it exists because users requested better visualization tools for matching methods. This collaborative development model ensures that HALCON addresses real-world challenges faced by machine vision practitioners.

Balance of Innovation and Stability

While introducing cutting-edge features like Continual Learning and optimized Deep OCR models, MVTec maintains HALCON’s reputation for reliability and stability. Each new feature undergoes rigorous testing, and the software continues to support existing applications while expanding capabilities.

Performance Benchmarks and Impact

The performance improvements in HALCON 25.11 translate directly into business value:

Speed Improvements

- 50× faster Deep OCR inference on embedded devices

- Multiple times faster deep learning inference for classification

- Optimized code reading with accelerated processing

Operational Benefits

- Reduced inspection time per unit, increasing throughput

- Lower hardware costs through efficient embedded deployment

- Faster time-to-market for new products via Continual Learning

- Decreased training costs with minimal image requirements

- Improved yield through more consistent quality control

Looking Forward: The Future of Machine Vision

HALCON 25.11 positions MVTec at the forefront of several important trends in machine vision and industrial automation:

Edge Intelligence

The ability to run sophisticated deep learning models on embedded devices aligns with the broader industry shift toward edge computing. As 5G networks and edge infrastructure continue to evolve, HALCON’s optimized models will enable increasingly distributed and intelligent manufacturing systems.

Adaptive Systems

Continual Learning represents a step toward truly adaptive machine vision systems that can evolve alongside production environments. Future developments in this area may enable even more autonomous adaptation, reducing the need for manual intervention in model maintenance.

AI Democratization

By making advanced deep learning capabilities accessible on affordable embedded hardware, HALCON 25.11 contributes to democratizing AI in manufacturing. Smaller manufacturers can now deploy sophisticated machine vision without massive infrastructure investments.

Sustainability

Efficient models that run on low-power embedded devices contribute to more sustainable manufacturing practices. Reduced power consumption, longer hardware lifecycles, and optimized resource usage align with growing environmental concerns in industry.

Getting Started with HALCON 25.11

For Existing HALCON Users

Existing HALCON users can upgrade to version 25.11 through the MVTec Software Manager. The transition is designed to be seamless, with backward compatibility for existing applications. New features are available immediately, and users can explore Continual Learning, optimized Deep OCR, and Score Visualization through provided example programs.

For New Users

Organizations evaluating machine vision solutions can access HALCON through various licensing options. MVTec offers evaluation licenses for testing, and comprehensive documentation helps new users get up to speed quickly. The company’s global network of distributors and partners provides local support and expertise.

Learning Resources

MVTec supports HALCON users with extensive resources:

- Webinars: Live sessions introducing new features and best practices

- Documentation: Comprehensive technical references and guides

- Example Programs: HDevelop examples demonstrating practical implementations

- Community: User forums and knowledge sharing

- Training: Official MVTec training courses and certifications

Conclusion

MVTec HALCON 25.11 represents a thoughtful evolution of mature machine vision software, delivering meaningful improvements where they matter most: speed, flexibility, and ease of use. The introduction of Continual Learning addresses a long-standing challenge in production machine vision, while optimized Deep OCR models enable real-time text reading on resource-constrained hardware.

These enhancements, combined with improved visualization tools and state-of-the-art classification models, strengthen HALCON’s position as a comprehensive solution for industrial machine vision challenges. By focusing on practical performance improvements rather than flashy features, MVTec continues to demonstrate its understanding of real-world manufacturing needs.

For manufacturers facing increasing demands for quality, speed, and flexibility, HALCON 25.11 offers tangible tools to meet these challenges. The software’s ability to adapt quickly to changing conditions, perform sophisticated analysis on affordable hardware, and deliver results in real-time makes it well-suited for modern manufacturing environments.

As industrial automation continues to advance and the expectations for machine vision systems grow, HALCON 25.11 provides a solid foundation for current needs while positioning users for future developments. The combination of proven reliability, continuous innovation, and customer-focused development ensures that HALCON remains a trusted partner in the ongoing evolution of intelligent manufacturing.

Whether deploying new machine vision applications or upgrading existing systems, HALCON 25.11 offers the performance, flexibility, and reliability that modern manufacturing demands. The future of machine vision is fast, adaptive, and intelligent—and with this release, MVTec demonstrates that the future is already here.