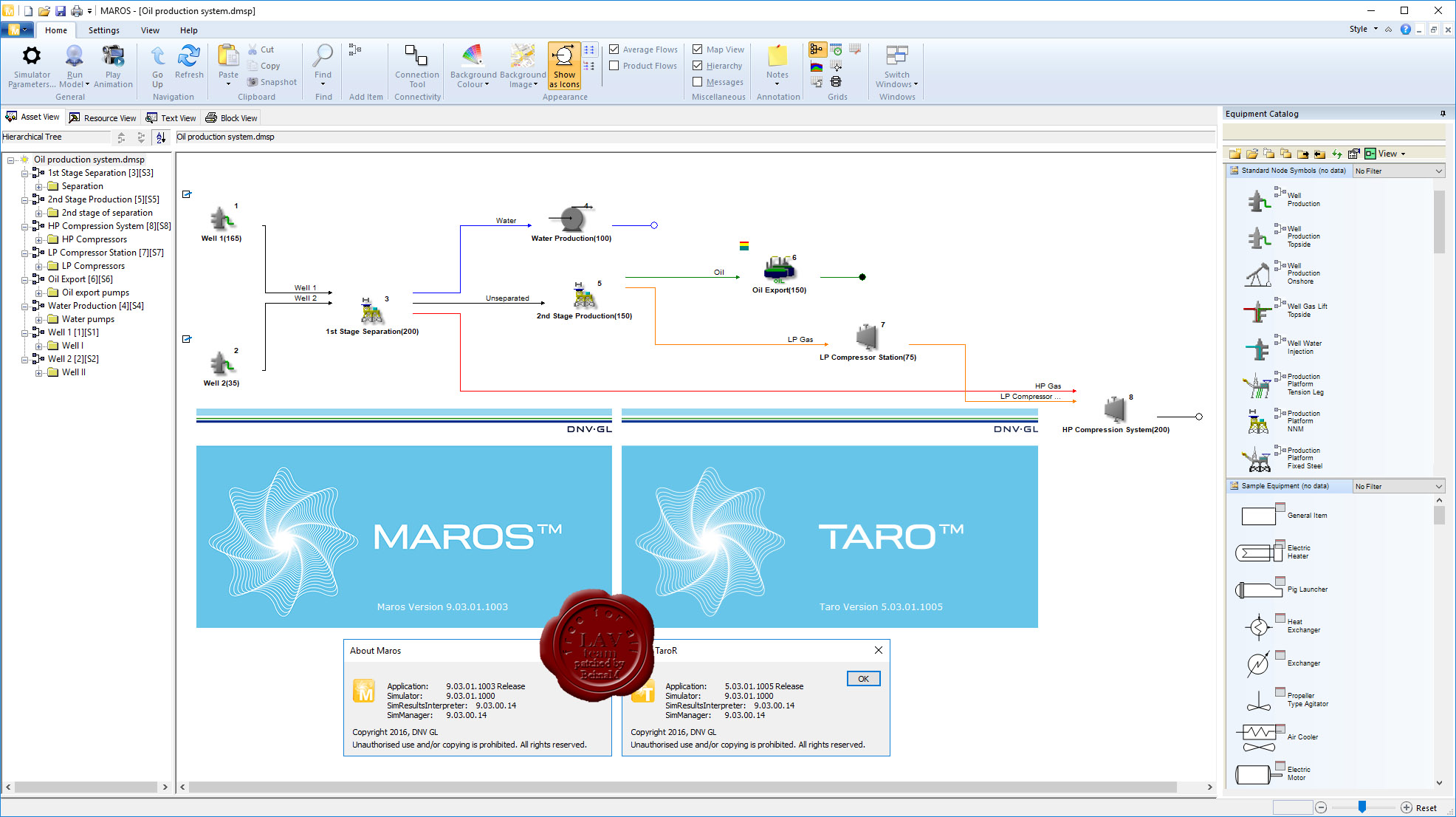

DNV GL Maros 9.03

€0.00

Download DNV GL AS Maros v9.03 + Taro v5.03

Specialized RAM analysis software in the oil and gas industry

Improve performance and reduce cost with Maros and Taro advanced tools for RAM (Reliability, Availability and Maintainability) studies.

Download DNV GL AS Maros v9.03 + Taro v5.03

Specialized RAM analysis software in the oil and gas industry

Improve performance and reduce cost with Maros and Taro advanced tools for RAM (Reliability, Availability and Maintainability) studies.

– Maros is a powerful RAM analysis software tool for predicting asset performance in the upstream oil and gas industry

– Discrete event-driven simulation

– Extensive flow modeling capability including divergent and convergent flow

– Highly intuitive graphical user interface

– Multi-level and multi-product criticality analysis ranking most critical items

– DNV GL has track record of 30+ years of RAM analysis software development

– World standard RAM analysis software for key players in the upstream oil and gas market

Upstream oil and gas software for RAM analysis:

Optimizing production and minimizing costs is a constant challenge. Key players in the oil and gas industry rely on Maros to make informed decisions about their assets. Our software development team has a history of over 30 years of working closely with super users. If you are facing a modeling challenge, most likely we have faced it and solved it.Key benefits of RAM analysis software for oil and gas with Maros software:

– Measure upstream oil and gas production availability/efficiency

– Debottlenecking via capacity analysis of the different systems present in a node

– Decision-making on actual productivity and financial figures of oil and gas assets

– Design optimization (oil storage tanks design, main processes, subsea assets, distribution systems etc.)

– Full supply chain modeling from wells via production platforms to tank farms

– Increase production efficiency, reduce operational expenditure, optimize capital expenditure of oil and gas assets with RAM analysis software-Reliability engineering practices during the design phase aims to optimize system robustness through measures such as redundancy or diversity in the design alternatives. This allows system designs based on user requirements and alternatives to be formulated and evaluated in a more holistic approach. Maros RAM analysis software can be applied throughout the entire project asset lifecycle.

Petrochemical plant process solutions with Taro:

What you get with Taro chemical process software:

– Proven track record: Taro has been used for analyzing numerous projects related to refinery designs, petrochemical plant process and associated supply chain logistics

– Ability to handle multiple feedstock and product streams along with complex buffer and operational strategies

– Great flexibility for handling complex configurations and situations outside the normal scope of system design

– Focus less on input operations and more on using results to improve petrochemical plant process performance

– Intuitive management of the system under analysis

– Reports are easy to understand

Applied process design for chemical and petrochemical plants:

Owners and operators in the downstream oil and gas industry need to make decisions on applied process design for chemical and petrochemical plants and the design, operation and maintenance of their plants based on the most accurate information available. Taro chemical process software supports this decision-making process through RAM (reliability, availability, maintainability) analysis. With Taro you can evaluate the performance of a single unit or include all the complexity and interdependence of petrochemical refineries, petrochemical complexes, oil and gas distribution networks, utility plants and the full supply chain, including product transportation (shipping, rail, road, pipelines ) and tank farms.

With Taro software you can:

– Optimize configuration with applied process design for chemical and petrochemical plants

– Assess maintenance strategies for downstream oil and gas facilities

– Evaluate operational flexibility of refineries and petrochemical plants

– Build a business plan with sales strategy based on accurately simulated performance figures

– Evaluate the influence of key parameters critical to success

– Understand the financial impact of decision and the return on investment (ROI) of each option

Maros + Taro

Maros is an advanced RAM analysis software tool specifically developed for analyzing reliability, availability, maintainability for the upstream oil and gas industry. It includes extensive features for modeling flow networks, maintenance strategies, typical oil and gas upstream operations, transport logistics and storage tanks. With Taro chemical process software you can model complex downstream oil and gas process plant systems and make optimal decisions on design, operation and maintenance based on a quantitative performance analysis. Raw plant data such as mass balance, design configuration and reliability data can be integrated into a digital twin of the plant, ensuring that your refinery design and/or petrochemical plant process is better represented, leading to a more accurate performance prediction. Finally, each parameters can be changed in ‘what-if’ scenarios that assist on assessing the impact of optimizations of key performance drivers.

Maros + Taro / Maros + Taro

Maros and Taro are two powerful software products of DNV GL, which are specially designed to conduct RAM studies (reliability, accessibility and maintainability) in upstream and downstream industries. Maros software is specially designed for upstream industries including E&P or exploration and production. This software provides engineers with unique features such as flow network modeling , maintenance strategies review, simulation of upstream oil and gas operations, transportation logistics, and maintenance tankers. While focusing on the life cycle of the downstream industrial unit, Taro software enables you to easily model complex industrial processes and make critical decisions in design, operation and maintenance based on quantitative analysis.

One of the special features of these two softwares is the ability to accurately estimate the efficiency of the industrial unit through basic raw information such as mass distribution, design configuration and reliability data. During all stages of modeling and working with the software, it is possible to change the parameters by “What? There is a “what-if” that makes the design conditions suitable for variable and volatile data entry. Although these two softwares operate independently, the performance of one without the other is meaningless, and for this reason, these two softwares are always presented together and work with each other. For oil and gas industrial design or optimization, all upstream and downstream industries need to coordinate with each other.

Key features of Maros and Taro software:

– advanced flow modeling capability including convergent and divergent flows

– ranking of the most key items in multi-product and multi-stage designs

– design of refinery, petrochemical and primary resource supply logistics units

– multi-feed implementation capability with complex buffers and strategies Operational

– High flexibility in extensive and complex configurations and unusual conditions

– Less focus on input operations and more focus on using results to increase productivity

– Easy management of the collection being analyzed and preparation of complete and easy-to-read reports

– Global standard software To study RAM with a history of 30 years – fully graphical user

interface

Related products

Mining Industry

Mining Industry

Mining Industry

Mining Industry

Mining Industry

Mining Industry

Geology

Mining Industry

Geology

Oil and Gas

Mining Industry

Geology

Mining Industry

Mining Industry

Mining Industry

Oil and Gas

Geology

Geology

Mining Industry

Mining Industry

Mining Industry

Geology

Mining Industry

Mining Industry

Geology

Mining Industry

Mining Industry

Science Research

Mining Industry

gexcel reconstructor 4.4.1 PROCESSING SOFTWARE FOR LIDAR DATA

Oil and Gas

Mining Industry

Mining Industry

Mining Industry

Geology

Mining Industry

Geology

Mining Industry

Geology

Mining Industry

Mining Industry

Mining Industry

Mining Industry

Mining Industry

Oil and Gas