Hexagon VISI 2025.2 modelling and drafting

€0.00

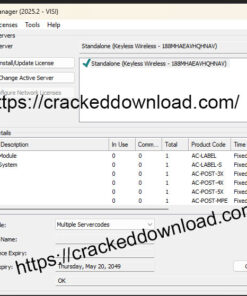

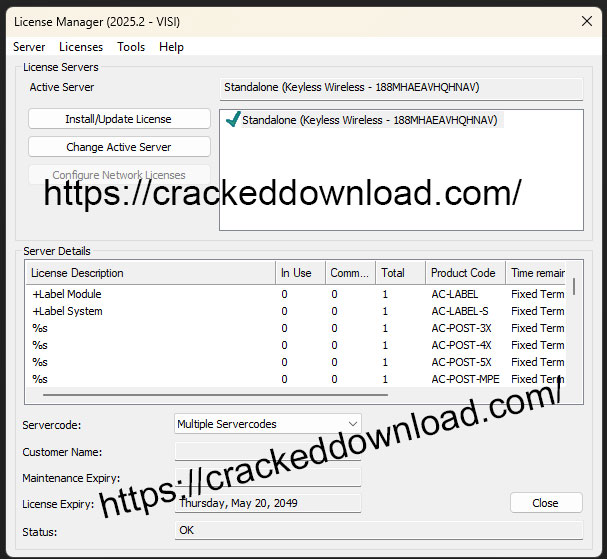

Hexagon VISI 2025.2 crack license download Hexagon Manufacturing Intelligence typically releases annual updates to its VISI software suite—a CAD/CAM/CAE solution tailored for the mold, die, and tooling industries Hexagon VISI 2025.2

Hexagon VISI 2025.2 crack license download modelling and drafting

Engineered for toolmakers, CNC programmers, and production teams who demand more. VISI 2025.2 helps you deliver better parts, faster. The Hexagon VISI 2025.2 release focuses on productivity and performance improvements, offering over 200 enhancements and resolving more than 250 bugs.

Here’s a breakdown of the key features and enhancements

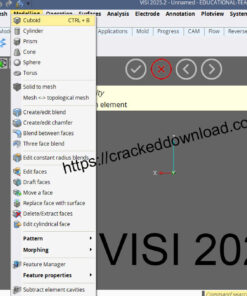

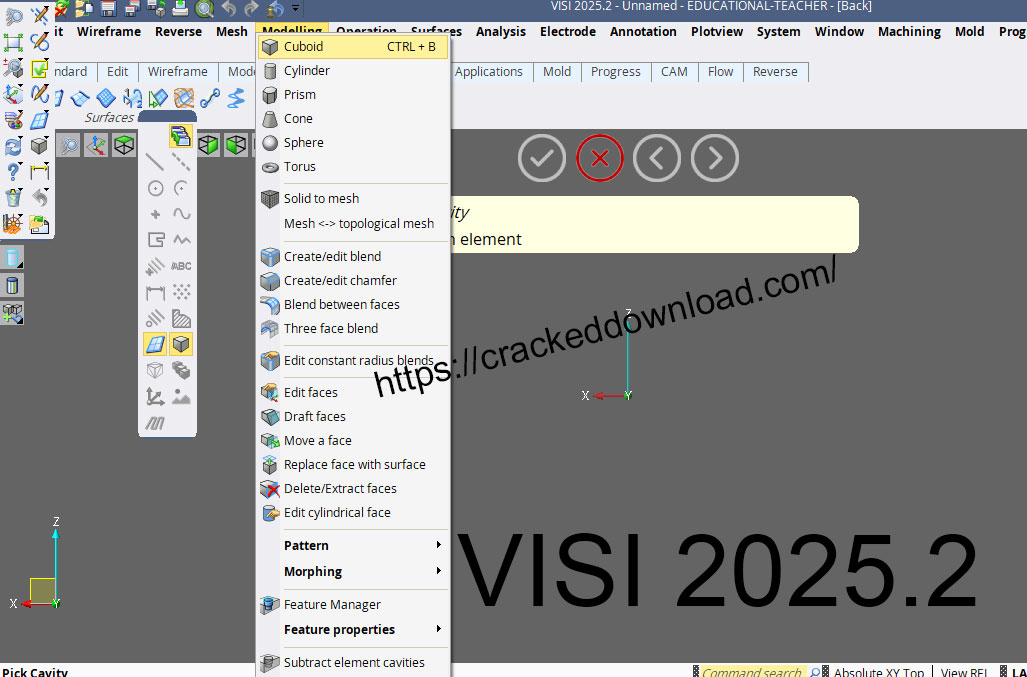

Modelling Enhancements

VISI 2025.2 provides significant improvements in modelling and drafting to speed up and facilitate model preparation, as well as enhance surface and solid modelling.

- Improved Assembly Manager Functionalities: Enhancements include automatic updating of function values via the “Update Values” icon, simplifying organization, efficiency, and collaboration. It also allows for non-uniform offset in the Bounding Box function, better management of table data when copying position fields, and easier drag-and-drop of parts into existing Families.

Plotview and Annotations Improvements: Ensures consistency in handling feature strings and a unified callout string in Annotations, significantly improving efficiency, accuracy, and consistency, and speeding up annotation introduction.

- Electrode Enhancements: Provides more controls and better solutions for electrode management, including default settings for Origins, holder insertion point control, checks to prevent errors during holder insertion, and improved electrode copying.

-

- Updated CAD Format Support: Brings updated format support to ensure compatibility with the latest formats, enhancing robustness and performance of 3D Modelling and InterOperability. Libraries have been consolidated for both import and export, leading to savings in file size and conversion speed.ACIS Reader support for ACIS 2025 1.0 with the Traditional library.

ACIS Writer support for ACIS 2025 with the Traditional library.

CATIA V5 Reader support for CATIA V5-6 R2025

CATIA V5 Writer support for CATIA V5-6 R2025 with the Traditional library

CATIA V5 Writer support for CATIA V5-6 R2024 with the Alternative library

CATIA V6 3DExperience Reader support for R2025x

FUSION 360 New Reader support for 2.0.21550 with the Alternative library

JTOpen Reader support for 10.10 with the Traditional library

JTOpen Writer support for up to 10.10 with the Alternative library

NX Unigraphics Reader support for NX 2412 Series (until 2412.3000 with the Alternative library)

Parasolid Reader/Writer update to 37.0.185

Rhino reader support for up to version 8 with the Traditional library

Solid Edge Reader support for Solid Edge 2025

SolidWorks Reader support for SolidWorks 2025 - Updated User Interface for Thickness Command: Features a new, easy-to-use user interface for the Thickness command.

- Enhanced Surface by 1drive 2shapes: Now supports multiple selections for drive elements.

- Circular Bend Command Control: Offers direction selection for greater control.

Mould and Die Advancements

These functionalities are designed to optimize production processes and improve the quality of final products.

- Consolidation of New Multi-stage Simulation: Includes review and improvement of forming/cutting operation options, general tool editing enhancements, and improved visualization of thinning results with dynamic sectioning. This reduces project time, provides detailed feedback for problem prediction, and optimizes production.

- Updated CAD Format Support: Brings updated format support to ensure compatibility with the latest formats, enhancing robustness and performance of 3D Modelling and InterOperability. Libraries have been consolidated for both import and export, leading to savings in file size and conversion speed.ACIS Reader support for ACIS 2025 1.0 with the Traditional library.

- Part Unfolding Improvements: Features automatic part recognition (including holes), improved “Coining” and flange unfolding, and the addition of step and multiple-step unfolding. These enhancements reduce project time, limit manual operations, and simplify the workflow.

-

- Standard Components Library Enhancements: Offers automatic chamfering and full threaded holes for TAPP features, improvements to screw insertion, enhancements to the ProDie group, and updated catalogues (Meusburger-Knarr-Intercom). This helps reduce project time and facilitates the use of standard elements.

Manufacturing (CAM) Innovations

Experience advanced machining strategies for superior results and a competitive advantage.

- New “Hybrid” Method for Global Roughing: This new technology from Hexagon’s shared components replaces the superseded HM Roughing method. It offers arc fitting, retract stepdown, and micro lift on back passes for a shorter, more optimized toolpath, allowing users to switch between methods within a single Roughing strategy, simplifying programming.

- Consolidation of Corner Remachining: Adds an additional contouring method to improve semi-finishing efficiency. It replaces old technology and includes new contouring methods like Split centre (default), Follow centre, and Morph to centre to control pass shape.

- Flowless Link between VISI and WORKNC: Enables users to seamlessly define and export geometry (faces, boundaries, stock, etc.) from VISI to WORKNC in a readable format, ensuring accurate transformation of design data into machinable data. This strengthens the Hexagon Mould and

- 4-Axis Pocketing in Wire Erosion: The introduction of a 4-Axis pocketing destruction cycle significantly improves efficiency, accuracy, and productivity in Wire EDM. It enhances traditional Wire EDM capabilities, allowing for the production of more complex, high-quality parts with greater consistency and reduced costs, providing manufacturers with a competitive edge.

Related products

Uncategorized

Uncategorized

Uncategorized

Uncategorized

unlimited find

Uncategorized

Oil and Gas

engineering softwares

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Dental Software

Science Research

Science Research

Uncategorized

Mining Industry

Science Research

Uncategorized

Uncategorized

Mining Industry

Uncategorized

Mathematical

Geology

unlimited find

Uncategorized

Simulation

Uncategorized

Uncategorized

Uncategorized

engineering softwares

scientific software

Uncategorized

Uncategorized

Cad/Cam

Mathematical

Uncategorized

unlimited find

Uncategorized

Uncategorized

Biomedical

Mathematical

Uncategorized