Mastercam is one of the most widely used computer-aided manufacturing (CAM) software in the world. Developed by CNC Software, Inc., it provides powerful tools for designing parts and creating accurate toolpaths for machining operations. Mastercam combines CAD (computer-aided design) and CAM (computer-aided manufacturing) capabilities, enabling engineers, machinists, and manufacturers to efficiently take a design from concept to finished product. Its versatility and ease of use have made it a standard in industries such as aerospace, automotive, medical devices, and general manufacturing.

⚙️ Purpose and performance

- The main function of a mastercam is to generate toolpaths that guide CNC machines in cutting, shaping, drilling or milling raw materials – such as metal, wood or plastic – into finished parts according to a digital design.

- This software bridges the gap between design and manufacturing, converting 3D or 2D models into machine code (G-code) that CNC machines understand.

Key components and modules

Mastercam includes several specialized modules designed for different types of machining:

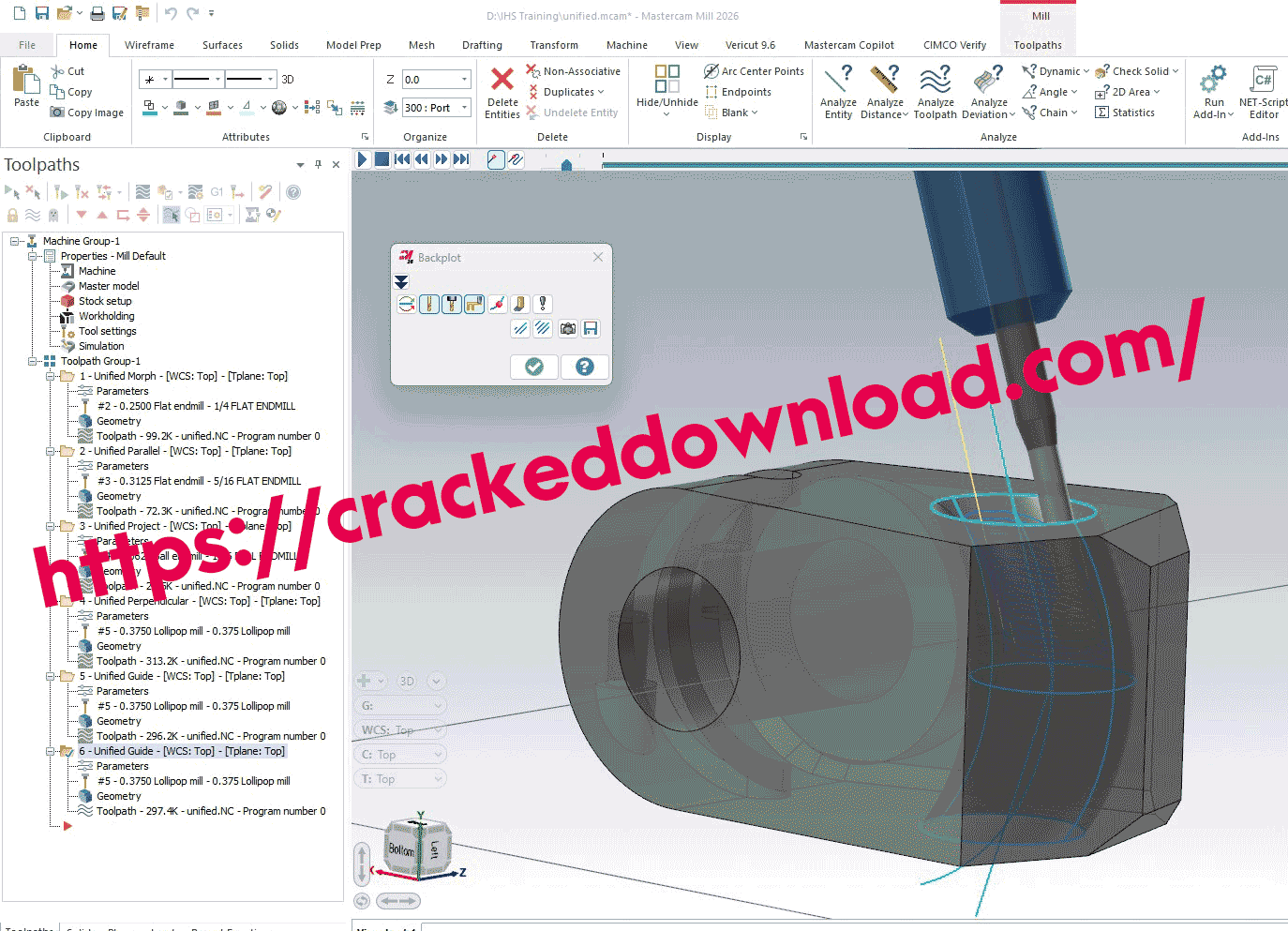

1. Mastercam Mill

- It is used for milling operations (2-axis, 3-axis, 4-axis and 5-axis).

- Supports roughing, finishing, contouring, pocketing, drilling, and high-speed machining operations.

- Advanced tool path strategies such as dynamic milling optimize cutting speed and tool life.

2. Mastercam Lathe

- Designed for turning and surface finishing operations on CNC lathes.

- It performs roughing, threading, grooving, drilling, and parting.

- Coordinates spindle and turret movements for multi-axis lathes.

3. Mastercam Router

- Used in wood and composite machining.

- Supports nesting, cutting, and contouring for 2D and 3D operations.

- It is popular in the furniture, cabinetmaking, and signmaking industries.

4. Mastercam Wire

- For wire EDM (electrical discharge machining).

- Creates 2-axis and 4-axis wire paths with precise control over cutting conditions.

- Ideal for molds, dies and complex contour parts.

5. Mastercam Design

- Provides CAD tools for design, modeling, and surface/solid creation.

- Allows importing and modifying geometry from other CAD systems.

- Integrated solid modeling enables combined surface and solid operations.

6. Mastercam Multiaxis

- Adds advanced 4- and 5-axis machining capabilities.

- It is used for complex geometries such as turbine blades, propellers, and aerospace parts.

- Provides collision checking, tool axis control, and tool path optimization.

Mastercam Features

1. CAD capabilities

Although Mastercam is primarily a CAM application, it also includes robust CAD features that allow users to design parts directly within the software. Users can create 2D sketches, 3D solid models, and surface geometries using visual tools. The CAD environment supports geometry editing, dimensioning, and solid manipulation, helping to streamline the design-to-manufacture process without the need for separate software.

2. CAM capabilities

The CAM section is where Mastercam really excels. The software offers a comprehensive set of machining strategies for different types of manufacturing processes:

- 2D machining: Includes contouring, drilling, boring, and surfacing operations.

- 3D machining: Enables complex surface milling, roughing, and finishing operations on free-form geometries.

- Multi-axis machining: Supports simultaneous 4-axis and 5-axis milling for complex, high-precision parts.

- Turning and Milling: Offers advanced toolpaths for lathes and multi-tasking machines, combining milling and turning into one package.

- Wire EDM: Provides precise tool paths for electrical discharge machining applications.

3. Toolpath generation and simulation

Mastercam’s toolpath engine produces highly efficient and optimized machining paths. Users can simulate the cutting process in a 3D environment to check for potential collisions, tool grooves, or overcuts before actual machining. This reduces the risk of tool damage and material waste, ensuring safer and faster production.

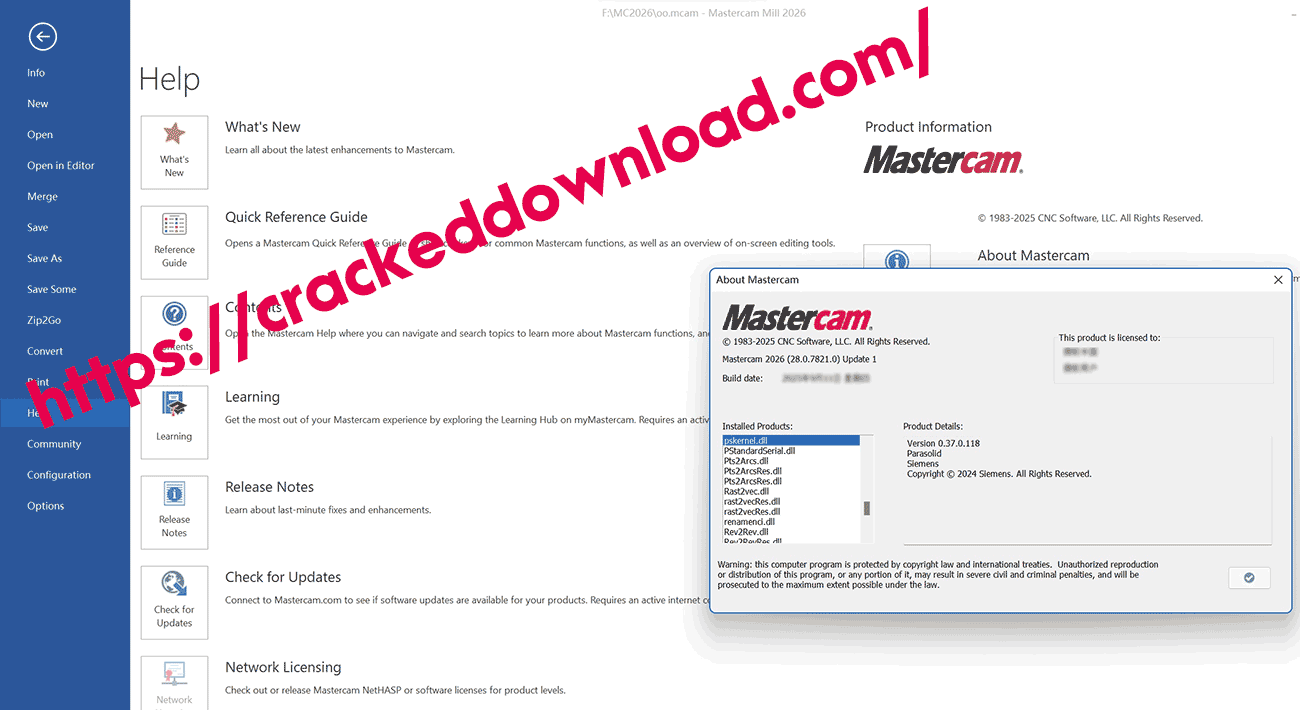

4. Post-processing

Once the toolpaths are validated, Mastercam converts them to G-code through its post-processing system. G-code is a set of machine-readable instructions that control CNC (Computer Numerical Control) machines. Mastercam supports a wide range of post-processors, allowing it to seamlessly interface with different makes and models of CNC machines.

5. Customization and Automation

Mastercam provides flexibility for customization. Users can automate repetitive tasks, create custom tool libraries, and even write macros using scripting tools. Its open architecture allows for integration with other software or hardware systems used in manufacturing workflows.

6. Analysis and verification tools

Mastercam includes measurement and verification features such as inventory analysis, toolpath comparison, and part deviation checking. These ensure that parts meet design specifications and that machining operations are optimized for time and material usage.

Industrial applications

Mastercam is used in various sectors:

- Aerospace: For high-precision aluminum or titanium parts.

- Automotive: For engine parts, molds and dies.

- Medical devices: for surgical instruments and implants.

- Tool and die manufacturing: for mold bases and parts.

- Woodworking: For cabinet making and furniture production.

- It supports prototyping and mass production, making it suitable for small workshops and large manufacturing centers.

️ Workflow overview

Draw or import geometry

Create parts in Mastercam or import from other CAD software (such as SolidWorks, AutoCAD, or STEP/IGES files).

Defining tool paths

Selection of machining strategies (e.g. contour, hole, drill, 3D surface).

Specify cutting tools, speeds, feeds, and steps.

Simulation

Use Mastercam simulation tools to check collisions, verify accuracy, and visualize material removal.

Post-processing

Generate G-code for your CNC machine using a postprocessor.

Send to device

Upload the code to the CNC controller and start machining.

Benefits of using Mastercam

- User-friendly interface: Combines design and machining in one software environment.

- High compatibility: Works with many types of machines and controller brands.

- Powerful optimization: Dynamic tool paths reduce machining time and wear.

- Strong support community: A wide range of tutorials, courses, and user forums.

- Reliable output: Trusted by manufacturers due to its accuracy and repeatability.

Educational and training application

Mastercam is also widely used in technical schools, colleges, and apprenticeship programs to train future machinists and engineers. Students learn the fundamentals of CNC programming, G-code basics, and real-world machining workflows through Mastercam’s user interface and simulation features.

Conclusion

Mastercam is recognized as a leading solution for computer-aided manufacturing due to its accuracy, versatility, and efficiency. The software bridges the gap between design and manufacturing by providing an integrated environment for CAD and CAM operations. Whether for simple 2D machining or complex 5-axis milling, Mastercam provides the tools needed to produce high-quality parts with speed and accuracy. For manufacturers looking to optimize their manufacturing processes and stay competitive in modern industries, Mastercam continues to be a trusted and powerful ally