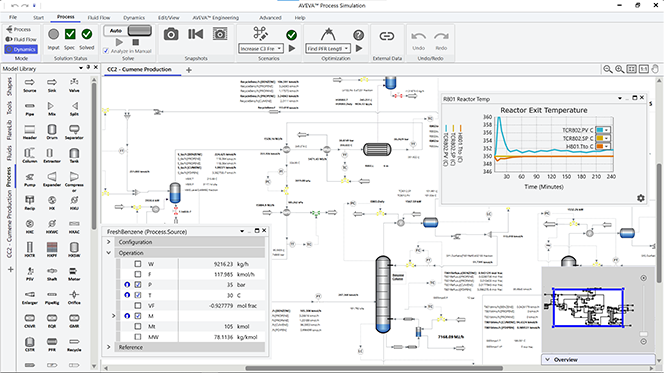

AVEVA Process Simulation 2026

€0.00

AVEVA Process Simulation 2026 crack license download, AVEVA Process Simulation is a powerful tool used for simulating and optimizing process systems. It’s widely used in industries like oil & gas, chemicals, pharmaceuticals, and utilities to help design, optimize, and troubleshoot processes before actual implementation. It allows engineers to model processes, test various scenarios, and predict the performance of the systems under different conditions.

AVEVA Process Simulation 2026 crack license download unlimited

AVEVA Process Simulation is a powerful tool used for simulating and optimizing process systems. It’s widely used in industries like oil & gas, chemicals, pharmaceuticals, and utilities to help design, optimize, and troubleshoot processes before actual implementation. It allows engineers to model processes, test various scenarios, and predict the performance of the systems under different conditions.

In terms of AVEVA Process Simulation 2026, while I don’t have specific information about the new features or updates of the 2026 version, here are some general trends and enhancements that are typically seen in newer releases of such software:

-

Improved Integration with Cloud & AI: Recent versions have likely continued to improve cloud-based simulation, allowing for more flexible and scalable simulations. AI-based analytics and optimization might also play a bigger role in helping engineers make better decisions.

-

Advanced Data Analytics: More powerful data processing and visualization tools may be introduced, allowing users to identify inefficiencies and optimize processes based on real-time data.

-

Enhanced User Interface (UI): UI/UX improvements to make the software more intuitive and user-friendly for both experienced and new users.

-

Integration with Other AVEVA Solutions: It may include even better integration with other AVEVA products (like AVEVA Engineering, AVEVA Process Control, and AVEVA Asset Performance Management), providing a more seamless experience across the lifecycle of process engineering, operations, and maintenance.

-

Increased Model Complexity and Accuracy: Better modeling capabilities for complex systems (e.g., multi-phase flow, dynamic simulation) and more accurate predictions for performance optimization and troubleshooting.

-

Real-Time Collaboration Features: With more people working remotely or in collaborative environments, it’s possible the new version will have enhanced real-time collaborative features for teams spread across different locations.

-

Sustainability and Energy Efficiency Modeling: Given the increasing focus on sustainability, newer versions might come with tools to model and optimize processes for energy efficiency and carbon footprint reduction.

What is new in AVEVA Process Simulation 2026

Key New Features

- Sustainability-focused design tools

Built-in modeling features to help engineers decarbonize process plants and move toward net-zero emissions. - Unified interface

A single, easy-to-use environment replaces multiple specialized programs, streamlining workflows across the plant lifecycle. - Multi-discipline collaboration

Engineers from process, utility, control, and mechanical disciplines can collaborate seamlessly, exploring all dimensions of plant design. - Online simulation & digital twin integration

Ability to bring simulations online with live operations data, replicate process conditions, monitor KPIs that can’t be measured directly, and troubleshoot issues virtually. - Cloud-enabled collaboration

Enhanced cloud features for sharing models and working across teams, improving efficiency and reducing project turnaround times.

Design sustainable processes at the speed the market demands with the innovative, integrated platform that enables a circular, sustainable world

Work smarter now for a sustainable future

AVEVA Process Simulation brings agility to the entire process life cycle—design, simulation, training, and operations. Build an integrated digital twin for your entire plant life cycle and use the same process model throughout every engineering phase.

Engineers can collaborate across disciplines in a single integrated platform to explore all dimensions of a potential design. For each engineering process, they’ll be able to quantify the impact on sustainability, feasibility, and profitability.

A single platform unlocks value across the process lifecycle

Conceptual design

Find the optimal design through fast evaluation of design alternatives with flexible specifications and continuous solving.

FEED

Specify optimal equipment by modeling interacting systems and directly populating the engineering database.

Detailed engineering

Design verification discovers errors earlier and saves time and money spent correcting them.

Start-up

Reduce risk of delays and lost revenue by ramping up quickly.

Operations

Predict problems before they occur. Train a highly competent workforce.

Related products

unlimited find

Science Research

Uncategorized

Uncategorized

Uncategorized

Science Research

Geology

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Dental Software

Uncategorized

Uncategorized

chemistry software

Geology

Uncategorized

Science Research

Uncategorized

Uncategorized

unlimited find

Simulation

Uncategorized

unlimited find

Mining Industry

Science Research

Science Research

Uncategorized

Biomedical

Uncategorized

unlimited find

Uncategorized

Mathematical

Simulation

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Oil and Gas

engineering softwares

Uncategorized

unlimited find