CONVERGE Studio v5.1.1 fluid dynamics

€0.00

CONVERGE Studio v5.1.1 fluid dynamics full crack license download,

CONVERGE Studio v5.1 is the graphical user interface (GUI) and pre/post-processing environment for CONVERGE CFD, a solver developed by Convergent Science.

CONVERGE Studio is the graphical user interface (GUI) that accompanies the CONVERGE CFD solver. It provides a visual environment where users can set up, run, and analyze CFD simulations without resorting solely to text-based input files.

CONVERGE Studio v5.1.1 fluid dynamics full crack license download,

CONVERGE Studio v5.1 is the graphical user interface (GUI) and pre/post-processing environment for CONVERGE CFD, a solver developed by Convergent Science.

In the 2025-2026 timeline, Version 5.x represents a significant expansion beyond internal combustion engines (ICE) into electrification, alternative fuels, and general fluid dynamics, while retaining its signature “autonomous meshing” technology.

CONVERGE is a leading computational fluid dynamics (CFD) software package with an emphasis on accuracy, efficiency, and innovation. With truly autonomous meshing, state-of-the-art physical models, and the ability to easily accommodate complex moving geometries, CONVERGE is fully equipped to help you solve the hard problems.

Innovative Meshing

CONVERGE features fully autonomous meshing, which eliminates all user meshing time from the simulation process. In addition, CONVERGE’s novel cut-cell approach perfectly represents your geometry—no matter how complex—and easily accommodates moving boundaries. This approach avoids the numerical viscosity generated by deforming meshes and offers accurate results without intensive hands-on setup. Moreover, Adaptive Mesh Refinement allows you to efficiently achieve the best solution possible for a given computational expense by adding cells when and where they are needed to resolve key flow phenomena.

Capture Essential Physical Processes

Going beyond a visually appealing simulation to obtaining useful, realistic results requires accurate physical modeling. CONVERGE contains an extensive suite of well-validated physical models for simulating everything from fluid-structure interaction and conjugate heat transfer to spray and combustion. In addition, CONVERGE includes the SAGE detailed chemistry solver, which is fully coupled with the flow solver for maximum accuracy and efficiency. If you’re interested in implementing a custom model, you can easily do so through user defined functions (UDFs) to customize CONVERGE to meet your needs.

Accelerate R&D

CONVERGE is designed to simplify and expedite the research and design process for an expansive range of applications, from gas turbine engines to mechanical heart valves. With CONVERGE, you can perform a comprehensive system analysis and optimization to find the best design before building an expensive physical prototype. Since 3D CFD simulations can require long runtimes, CONVERGE enables highly parallel simulations on many processors and demonstrates excellent scaling even on thousands of cores. Taking advantage of these capabilities can drastically reduce time-to-solution for your simulations. Overall, incorporating CONVERGE into your R&D workflow can reduce costs across the board and enable you to bring your product to market sooner.

What’s New in CONVERGE 5?

CONVERGE 5, the latest major release of our CFD software, includes many exciting new features and enhancements that expand both the capability and usability of the code across industries and applications.

Rockets

The conditions inside of a liquid rocket combustor span an immense range of pressures and temperatures during operation. Combustion temperatures can reach 200 times the temperatures of stored propellant, and pressures in the injector and combustion chamber are orders of magnitude greater than at the nozzle exit. In addition, phase change is omnipresent, with opportunities for vaporization as the liquid fuel or oxidizer cools the engine on its path to the combustion chamber, cavitation in the turbopumps or injectors, solidification as ice forms near the cold walls, and condensation at the nozzle outlet. These changes in phase can occur even before the combustion reactions convert the fuel and oxidizer into gas-phase products to propel the device. To accurately simulate liquid rocket combustors, you need to be able to capture the phase transitions and associated property changes under these extreme conditions.

1. CONVERGE Studio v5.1.1 What Makes CONVERGE Unique?

Unlike traditional CFD software (like Ansys Fluent or Star-CCM+) that requires manual generation of a static mesh, CONVERGE is defined by Autonomous Meshing.

-

Runtime Meshing: The grid is generated automatically at every time-step during the simulation.

-

Adaptive Mesh Refinement (AMR): The software automatically adds grid resolution where physics requires it (e.g., high-velocity gradients or flame fronts) and removes it where it isn’t needed.

-

Zero User Meshing Time: You import a water-tight CAD geometry, set boundary conditions, and run. There is no manual “meshing” phase.

2. Key Features in Version 5.1 CONVERGE Studio v5.1.1 crack

Building on the major Version 5 release (May 2025), v5.1 refines the following capabilities:

A. Electrification & Battery Modeling

v5.1 is heavily optimized for the EV market.

-

Battery Thermal Runaway: Specialized models to simulate the propagation of thermal runaway in battery packs, including vent gas generation and combustion.

-

Electric Motors: Enhanced cooling simulation capabilities (oil spray cooling) for e-motors.

-

Hydrogen: Updated combustion models specifically tuned for hydrogen engines and fuel cells.

B. Real-Fluid Models & GPU Acceleration

-

Unified Equation of State: A new real-fluid model treats fluids as a single substance that can transition between liquid and gas phases seamlessly. This is critical for liquid rocket combustors and high-pressure injectors.

-

GPU Solver (Beta/Limited): v5 introduced the ability to run specific solver functions on NVIDIA GPUs to drastically speed up turnover times for large transient simulations.

C. 1D-3D Coupling

-

Built-in 1D Solver: You can now simulate long pipes or ducts using a fast 1D solver while coupling it to the 3D domain for the main chamber. This allows for full-system simulation without the computational cost of a full 3D mesh.

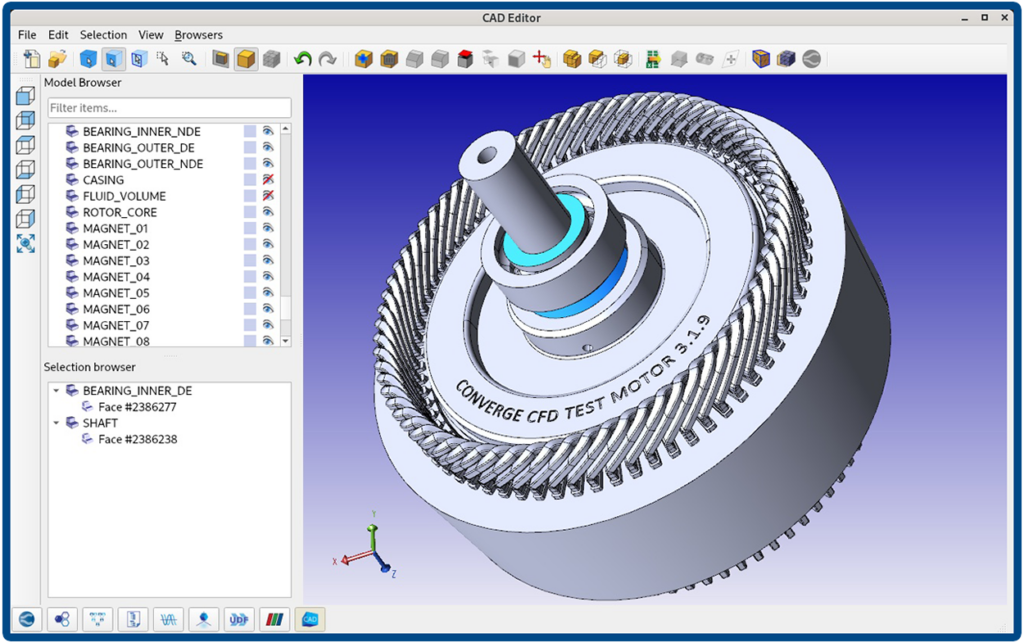

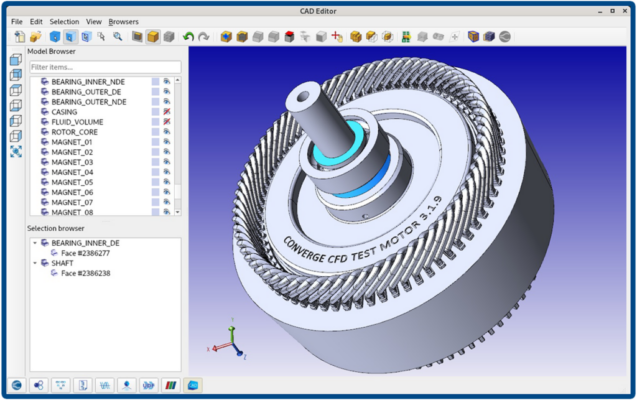

3. The “Studio” Component (The Interface) CONVERGE Studio v5.1.1

CONVERGE Studio v5.1 is where you set up the case. New workflow tools include:

-

Integrated CAD Editor: You can now clean up, repair, and modify CAD geometry directly inside Studio (powered by Polygonica), reducing reliance on third-party CAD repair tools.

-

Machine Learning (ML) Optimization: A built-in ML tool helps you run rapid design optimization studies without needing external optimization software.

-

Visual-Environment Integration: Enhanced compatibility with post-processors like Tecplot (often bundled) and Paraview.

4. Typical Workflow

-

Geometry Import: Load

.stlor.datsurface files into Studio. -

Surface Flagging: Assign boundaries (e.g., “Inlet,” “Piston,” “Wall”) in Studio.

-

Case Setup: Select physics (Turbulence, Spray, Combustion, etc.) and Material properties.

-

Export & Run: Studio exports the

.ininput files. The CONVERGE Solver (command line) runs the simulation. -

Post-Processing: Load 3D output files back into Studio (or Tecplot) to visualize flow, temperature, and species.

Related products

Mathematical

Uncategorized

Mathematical

Uncategorized

Uncategorized

Uncategorized

Oil and Gas

Uncategorized

Uncategorized

Mining Industry

Science Research

Uncategorized

engineering softwares

Science Research

Uncategorized

Uncategorized

Uncategorized

Simulation

Uncategorized

Uncategorized

Uncategorized

Science Research

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Science Research

Biomedical

unlimited find

unlimited find

Mining Industry

Dental Software

Uncategorized

Uncategorized

Uncategorized

unlimited find

Uncategorized

engineering softwares

Uncategorized

Science Research

Uncategorized

Uncategorized

Uncategorized

Uncategorized

unlimited find

Science Research