hyperMILL 2025 full crack download

€0.00

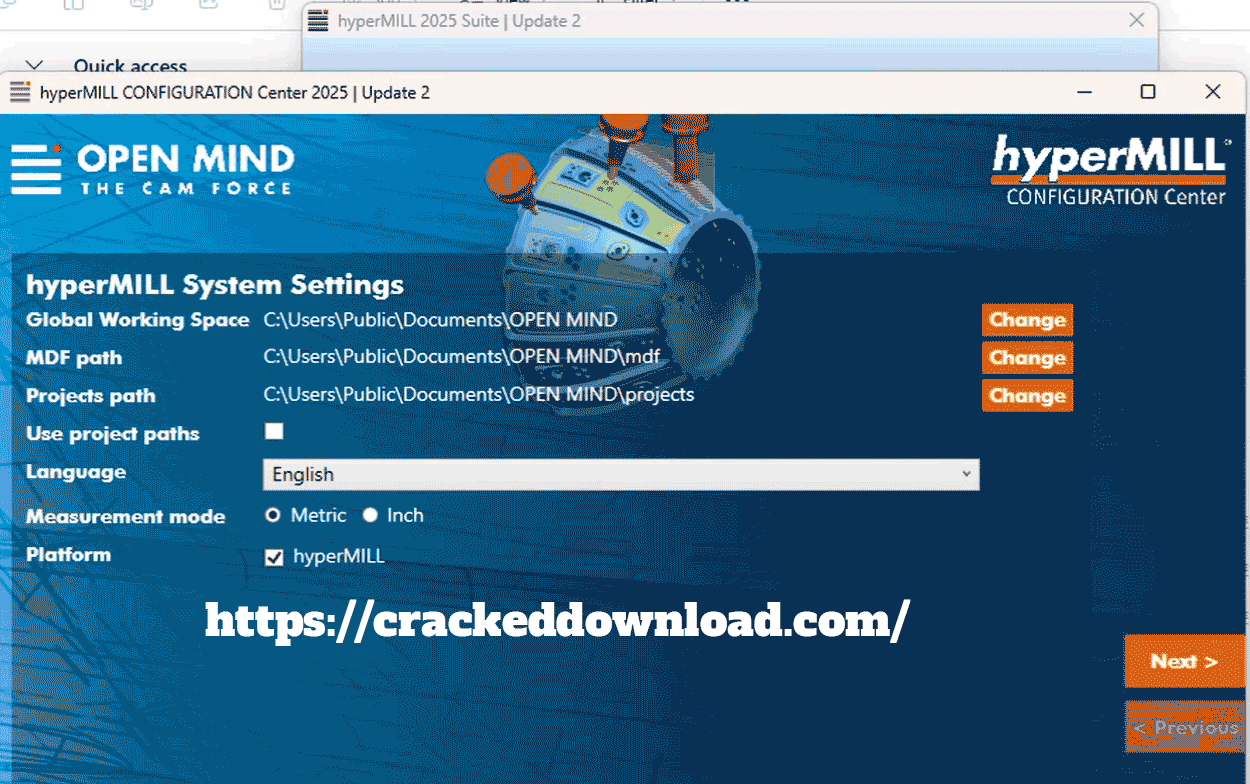

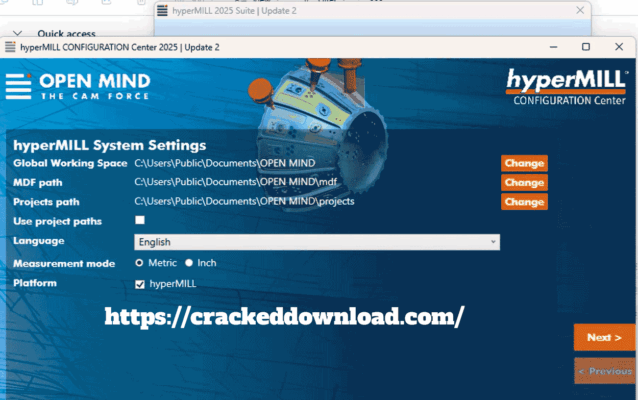

hyperMILL 2025 full crack download hyperMILL 2025, developed by OPEN MIND Technologies, is a high-performance CAD/CAM software suite designed for advanced manufacturing in industries like automotive, aerospace, and precision engineering.

hyperMILL 2025 full crack download

hyperMILL 2025 offers you even more performance and efficiency, both for CAD and CAM.

hyperMILL CAD/CAM software: What’s new in 2025?

With the new tessellation algorithm and the new, simplified element display for CAD models, as well as improved algorithms of our 3D strategies, you benefit from noticeably faster working and even more precise processing results.

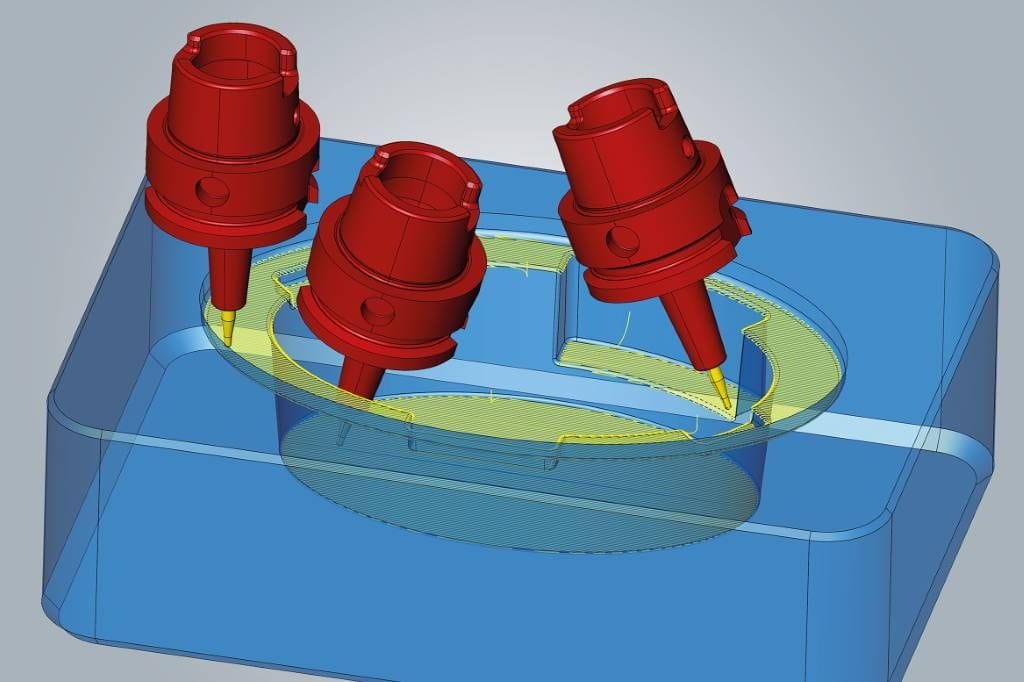

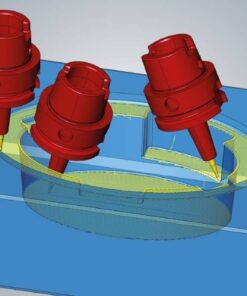

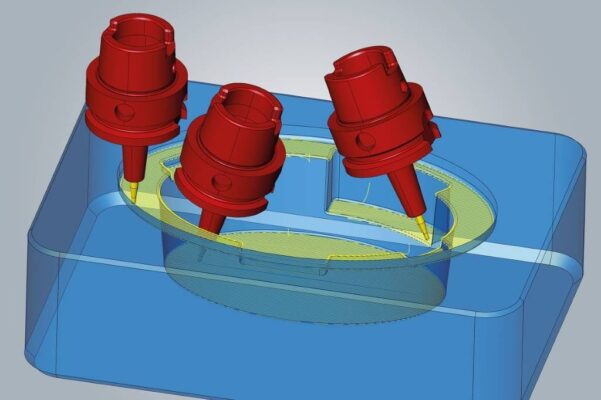

A highlight of the new hyperMILL release are three innovative strategies for deburring holes and part edges – for maximum flexibility and the highest quality. In addition, the new 5-axis automatic tool orientation mode ensures optimized machining, enabling efficient and reliable tool paths, even for the most complex components.

3D Optimized Roughing

The pocket milling algorithm has been redeveloped for the roughing mode of the strategy in order to achieve greater efficiency during roughing and better machining control. A benefit of the new version is realized when machining with large lateral infeeds and remaining material. Additionally, you can define a contour radius and a path radius, allowing you to better control toolpath roundings. The contour radius is used for toolpaths along the model geometry, while the path radius is used for all other offset paths.

Benefit: Faster rough machining and improved behavior with large infeeds and rest material.

New strategies for precise deburring

Burr-free edges and holes are not only functionally important, but also an essential component of a high-quality end product. With hyperMILL 2025 you have a comprehensive selection of deburring strategies available directly at the machine.

The optional license “5-axis Deburring” enables the use of both strategies: “5-axis Hole Deburring” and “5-axis Deburring” in 5-axis mode. The 3-axis mode is included as standard in the hyperMILL 3D package.

5-axis ISO Machining

Use our new 5-axis strategy* to machine individual or a few contiguous surfaces according to the course of the ISO lines (U and V). The functions that you are already familiar with from 3D ISO Machining can now also be used for 5-axis machining. In addition to feed adjustment for curvatures and 3D radius correction, the high-precision surface mode can be used with our True-Shape Technology.

Benefit: 5-axis machining of ISO surfaces with increased surface quality and programming support through intelligent algorithms.

*Licensing required.

5-axis Profile Finishing

We have fundamentally revised this strategy and offer you a new, improved version of 5-axis Profile Finishing. Many familiar and innovative features from “3D Profile Finishing” are now also available for 5-axis machining.

Additionally, the strategy offers a new algorithm for the automatic tool orientation strategy. Utilize familiar functions such as smooth overlapping, automatic milling surface extension, trimming to the milling area, adjustment of curvature feedrate, or 3D path compensation to make surface machining more efficient, easier, and faster.

With the option “True-Shape Point Distribution”, you achieve an optimal point distribution for machining. This leads to a higher surface quality and consistent machine movements.

Benefit: Faster and simplified programming, higher surface quality, and programming support through intelligent algorithms.

What to Expect from hyperMILL 2025 (Predictions & Trends)

While specific features for hyperMILL 2025 have not been publicly detailed yet, OPEN MIND typically enhances the following areas with each new version:

1. Enhanced 5-Axis Machining Strategies

- Improved collision avoidance and automation in 5-axis positioning.

- Smarter tilting and swiveling strategies for complex geometries.

- Optimization for turbine blades, impellers, and aerospace components.

2. Automation & CAM Standardization

- Expansion of hyperMILL® AUTOMATION tools.

- Better integration with hyperMILL® BEST FIT and hyperMILL® OPTIMIZE 3D for adaptive workflows.

- Enhanced template-based programming for repetitive tasks.

3. Integration with Industry 4.0 & Digital Twins

- Stronger support for digital twin technology.

- Improved data exchange with CAD systems (e.g., Siemens NX, Creo, SolidWorks).

- Cloud-based collaboration or licensing options (possible future direction).

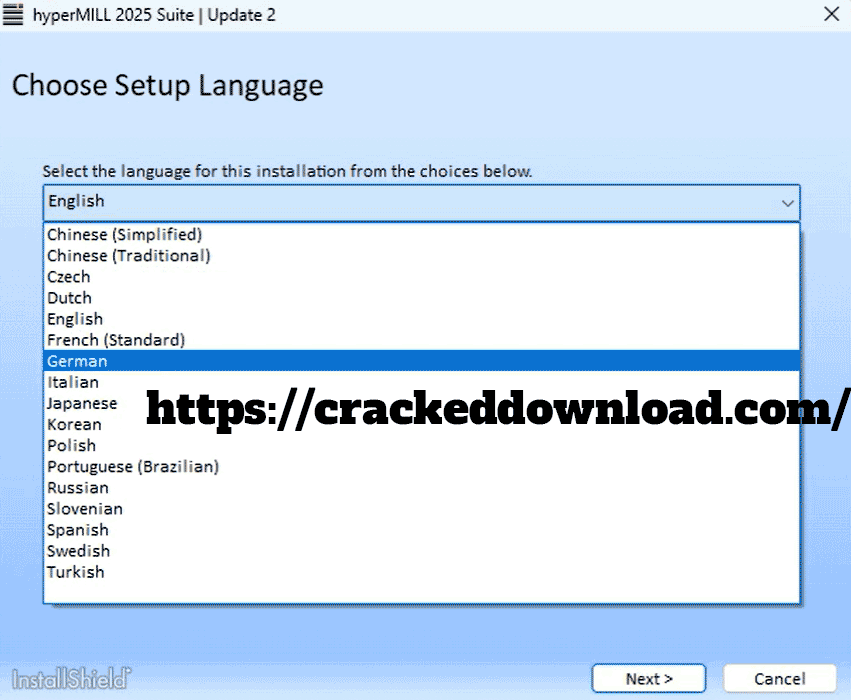

4. Improved User Interface & Performance

- Faster calculation times and smoother toolpath simulation.

- UI refinements for easier navigation and reduced programming time.

- Touch-friendly interface elements (if hardware supports it).

5. Additive Manufacturing & Hybrid Machining

- Enhanced support for 5-axis milling of additively manufactured parts.

- Better handling of near-net-shape components.

6. Toolpath Optimization & Efficiency

- More intelligent rest material detection.

- Smoother transitions in high-speed and high-efficiency machining (HPC/HSC).

- Improved finishing strategies (e.g., spiral, radial, and contour-driven toolpaths).

hyperMILL 2025, developed by OPEN MIND Technologies, is a high-performance CAD/CAM software suite designed for advanced manufacturing in industries like automotive, aerospace, and precision engineering. It offers a range of enhanced features and innovative technologies to optimize programming and machining processes for 2.5D, 3D, 5-axis, and mill/turn tasks. Below is an overview of its key features, improvements, and benefits based on available information:

Key Features and Enhancements in hyperMILL 2025

Advanced 5-Axis Machining:

Automatic Tool Orientation Mode: A new algorithm pre-analyzes tool paths to calculate optimal machining sequences, combining simultaneous and indexed tool movements. This reduces programming time and enhances efficiency for complex components.

5-Axis Hole Deburring Strategy: Simplifies deburring of sharp edges on holes and intersecting holes. The CAM Plan feature automatically recognizes holes and marks edges, calculating tool paths for both 3-axis (included in the hyperMILL 3D package) and 5-axis modes (requires optional license). Supports lollipop and ballmill cutters for fast and effective edge deburring.

5-Axis ISO Machining: Extends 3D ISO machining capabilities to 5-axis, allowing machining of individual or contiguous surfaces along ISO lines (U and V).

Additive Manufacturing Improvements:

Linking Job: Simplifies programming of complex additive processes by linking multiple additive jobs with different technology parameters and 5-axis strategies, ensuring an optimized workflow.

Adaptive Density Minimal Surfaces (ADMS): Incorporates an algorithm from Spherene Inc. to generate self-supporting infill strategies for 3D printed parts, reducing mass and optimizing material properties.

3D Machining Enhancements:

Pocket Milling Algorithm: Redeveloped for 3D-optimized roughing with high feed cutters, offering better control for large lateral in-feeds and remaining material. Allows definition of contour and path radii for improved toolpath rounding.

Dynamic Stock Technology: Automatically generates updated stock conditions for all machining jobs, optimizing linking movements via the hyperMILL VIRTUAL Machining Optimizer.

CAD Improvements:

Extrusion of Complex Sketches: Enables easy extrusion of complex sketches with defined angles of inclination, automatically trimming intersecting surfaces. Ideal for creating molds or electrodes without rework.

Switch Visibility On/Off: Improves performance for large assemblies by allowing layers to be set as non-selectable before loading, enabling smoother workflows for complex models.

New Tessellation Algorithm: Enhances CAD model processing with simplified element display for better performance.

Collision Control and Machine Model Integration:

Use VM for Calculation: Incorporates the machine model directly into tool path calculations, ensuring precise collision control and avoidance, especially in tight spaces or near machine limits. The “Smooth Overlap” option ensures seamless transitions for residual material rework.

Closest C-Angle Option: Allows specific control over positioning via a preferred C-axis position under the NC Solutions tab.

Automation and Integration:

hyperMILL 2025 continues to emphasize automation, offering feature and macro technology to standardize and automate CAD/CAM processes. It integrates seamlessly with CAD systems like SOLIDWORKS, CATIA V5, Creo, and Siemens NX, supporting PMI and MBD data imports.

The Hummingbird Manufacturing Execution System (MES) enhances process planning and control, ensuring consistent data flow across the production chain.

Turning and Mill-Turn Enhancements:

Improved postprocessors for main/sub-spindle applications on Siemens, Fanuc, and Mitsubishi (Mazak) controls.

Supports mill-turn machines with A/C kinematics for increased safety and process control.

Hypermill 2025 update2 OPEN MIND cracked license unlocked unlimited

Related products

scientific software

Science Research

Simulation

unlimited find

chemistry software

Uncategorized

Cad/Cam

Science Research

Uncategorized

Science Research

Uncategorized

Uncategorized

Science Research

Simulation

Mathematical

Uncategorized

Uncategorized

Dental Software

Science Research

Uncategorized

Geology

Uncategorized

Uncategorized

Biomedical

Uncategorized

Oil and Gas

Uncategorized

Geology

Mathematical

Uncategorized

Uncategorized

Uncategorized

engineering softwares

Cad/Cam

Uncategorized

Uncategorized

Uncategorized

unlimited find

Science Research

Uncategorized

Mining Industry

Uncategorized

Uncategorized