Moldex3D 2025 R3 plastic injection molding

€0.00

Moldex3D 2025 crack license,

Moldex3D 2025 R3 plastic injection molding Moldex3D 2025.3 crack license, Moldex3D has long been a leader in CAE (Computer-Aided Engineering) for plastics. However, earlier iterations often required a trade-off: you could have speed, or you could have granular accuracy.

Moldex3D 2025 R3 plastic injection molding Moldex3D 2025.3 crack license

Bridging the Gap Between Design and Reality: An Introduction to Moldex3D 2025 R3

In the high-stakes world of plastic injection molding, the difference between a profitable run and a scrap pile often comes down to the quality of the simulation. As manufacturing moves deeper into the era of Industry 4.0, the demand for “Digital Twins”—virtual models that behave exactly like their physical counterparts—has never been higher. Enter Moldex3D 2025 R3.

Released as the mature, stabilized update to the major 2025 platform, the R3 version focuses on refining solver accuracy, expanding material data, and streamlining the workflow for complex electronic and automotive components.

The Evolution of Simulation

Moldex3D has long been a leader in CAE (Computer-Aided Engineering) for plastics. However, earlier iterations often required a trade-off: you could have speed, or you could have granular accuracy. The 2025 R3 release aims to eliminate that compromise. By optimizing the kernel to utilize modern multi-core processors and Linux-based HPC (High-Performance Computing) clusters more effectively, R3 delivers results faster without sacrificing the depth of the thermal or flow analysis.

Key Innovations in R3 Moldex3D 2025.3 crack license

While the list of technical updates is extensive, three specific areas define this release:

1. Enhanced Electronics Packaging (IC Packaging) One of the standout features in R3 is the expanded capability for Electronic Potting simulation. As electronics become smaller and more powerful, heat dissipation becomes critical. R3 introduces advanced analysis for thermal pins and potting processes, allowing engineers to predict how encapsulants will flow around delicate microchips and wires, preventing “wire sweep” and ensuring proper thermal management.

2. The Crystallinity Breakthrough For manufacturers working with semi-crystalline materials (like PA66 or PBT), warpage has always been difficult to predict because it depends heavily on how the plastic crystallizes during cooling. Moldex3D 2025 R3 now outputs detailed crystallinity results. This allows users to visualize exactly how the molecular structure forms during the cooling phase, providing a much more accurate prediction of final shrinkage and structural integrity.

3. Smarter Pre-Processing Simulation engineers often spend more time fixing CAD models than running analyses. R3 tackles this with the Cooling Channel Loop Wizard and improved auto-repair tools. These features automatically detect and fix gaps in geometry and logically connect complex cooling networks. This drastically reduces the “click-time” required to set up a model, allowing engineers to move straight to analysis.

The “Green” Factor

Efficiency isn’t just about speed; it’s about sustainability. By improving the prediction of defects like air traps and weld lines before the mold is cut, Moldex3D 2025 R3 helps reduce physical mold trials. Fewer trials mean less energy consumed and less plastic wasted. Furthermore, the updated material database includes new data on recycled plastics and biopolymers, supporting the industry’s shift toward circular economy materials.

Moldex3D 2025.3 crack license

Moldex3D 2025 R3 is more than just a software update; it is a maturity milestone for the 2025 platform. For engineering teams looking to reduce time-to-market and increase confidence in their mold designs, R3 offers a robust, data-driven solution that bridges the gap between digital design and physical reality.

Moldex3D 2025 New Features

As the plastic injection molding industry moves towards greater efficiency and intelligence, how can businesses stand out in an increasingly competitive market? Moldex3D 2025 takes simulation accuracy and process support to the next level, enabling more precise defect predictions and faster analysis speeds, allowing engineers to make critical design decisions with confidence.

In addition, Moldex3D 2025 introduces automation and AI-powered collaboration. From process parameter settings to gate and mold design optimization, it provides intelligent recommendations, significantly reducing mold tryout and development time. This ensures smoother workflow while guaranteeing both efficiency and accuracy in product development. Explore Moldex3D 2025 today and experience the transformative power of smart simulation!

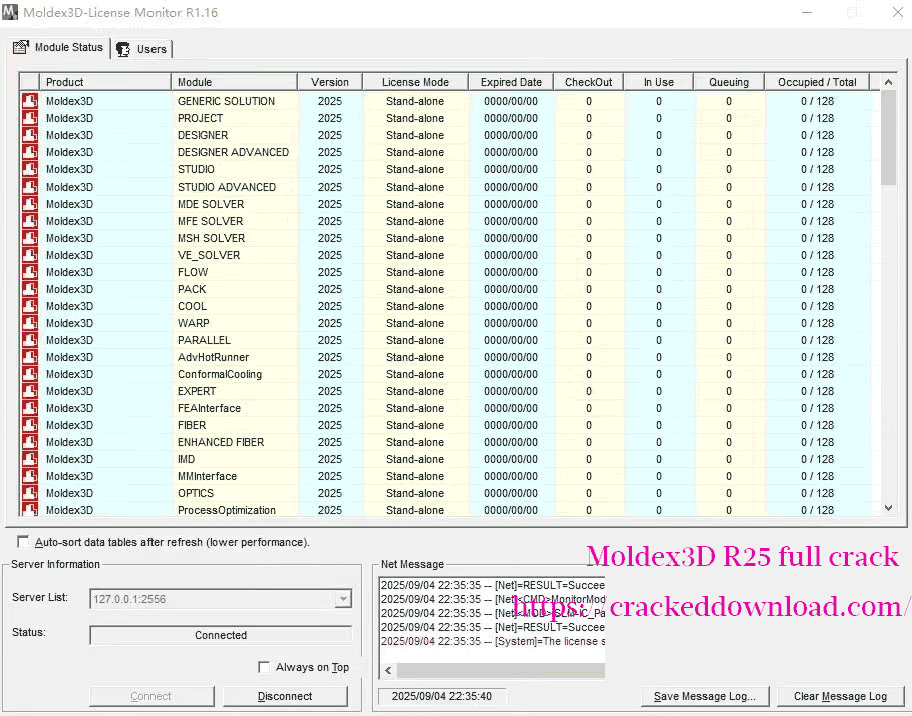

Simulation

Moldex3D 2025 has undergone a comprehensive upgrade in simulation capabilities: The solver has been optimized for hot runner injection pressure prediction and heat dissipation analysis with thermal pins, along with the addition of crystallinity output. The IC module now includes a gold wire delamination warning, providing more powerful IC modeling capabilities and enhancing preprocessing efficiency. In the Mesh module, Multi-Component Molding mesh construction has been improved, and a cooling channel curve connection repair tool has been added. Studio now offers more flexible viewpoint controls, standardized reports, and enhanced DOE capabilities, enabling users to perform simulation analyses more efficiently and accurately.

Comprehensive Hot Runner Injection Pressure Simulation Enhancements

Moldex3D has always provided accurate predictions for compressible flow calculations. In Moldex3D 2025, we have further optimized this functionality to more precisely simulate the behavior of molten plastic in ultra-thin parts and hot runners. These enhancements improve the accuracy of predicting pressure fluctuations caused by geometric thickness and fluid compressibility, effectively reducing their impact.

Additionally, cavity pressure prediction for amorphous materials has made continuous breakthroughs. By integrating material measurements into a digital twin process and considering the effects of pressure on viscosity, Moldex3D significantly improves the consistency between simulated and experimental cavity pressure during injection and packing. This enables engineers to precisely monitor molding pressure variations, further optimizing the manufacturing process and product quality.

Gain More Detailed Warpage Analysis with Crystallinity Output

In crystalline plastics, crystallinity significantly impacts product physical and mechanical properties and warpage during injection molding. In some cases, post-crystallization effects may even lead to quality issues.

To address these challenges, Moldex3D continues to refine its consideration of crystallization. It not only accurately simulates crystallization effects under high-speed cooling but also incorporates the Dual Nakamura model to enhance the realism of crystallinity calculations.

With the newly introduced crystallinity output feature, users can monitor crystallinity status in real-time during warpage and even annealing stages. This enables precise simulation of deformation caused by post-crystallization, helping users analyze and optimize the molding process to improve product quality and reliability.

Related products

Uncategorized

engineering softwares

Science Research

Mathematical

Uncategorized

Simulation

Uncategorized

Cad/Cam

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Science Research

Uncategorized

unlimited find

Uncategorized

Uncategorized

Uncategorized

chemistry software

Uncategorized

Uncategorized

Uncategorized

unlimited find

Uncategorized

Uncategorized

Simulation

Uncategorized

Mathematical

Oil and Gas

unlimited find

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Geology

Geology

Mathematical

Uncategorized

Uncategorized

Uncategorized

unlimited find

Science Research

Uncategorized