Siemens Fibersim 17.1.2

€0.00

Siemens Fibersim 17.1.2 full crack download

FiberSIM

The nature of fiber-reinforced plastic products require rapid changes in the way analysis, design and manufacturing is traditionally performed. Unravel the complexities of these materials with the FiberSIM portfolio of software.

Siemens Fibersim 17.1.2 full crack download

FiberSIM

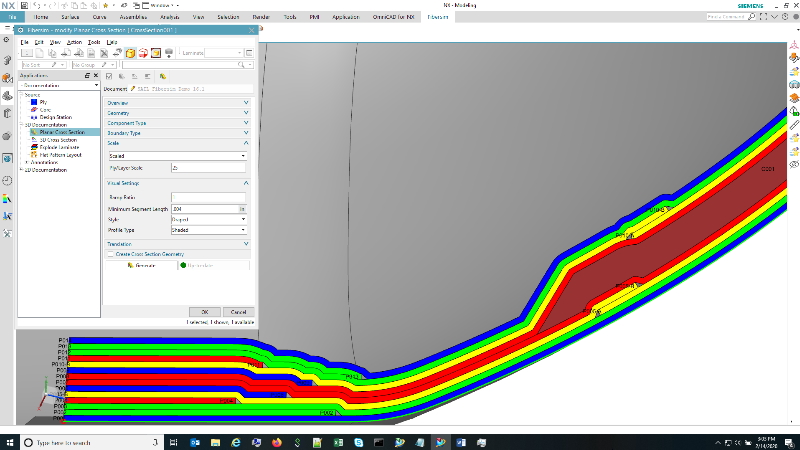

The nature of fiber-reinforced plastic products require rapid changes in the way analysis, design and manufacturing is traditionally performed. Unravel the complexities of these materials with the FiberSIM portfolio of software. Experience a concurrent engineering process where analysis and design are performed in the context of the manufacturing process, which is key to developing optimal designs. The open architecture of Fibersim provides a specialized engineering environment to create a composite digital twin in NX, CATIA, or CREO.

Composite Design & Analysis

Using Fibersim as the hub for your composite part design allows for the efficient input of requirements from CAE to create a CAD digital twin that can rapidly react to changes in shape and specification, all while providing a window onto the shop floor to ensure the producibility of your design. Design rules provide powerful automation in the creation of ply boundaries from minimal geometry input. Additionally advanced sorting, filtering, and renaming capabilities provide efficient tools for navigating the complexity of modern composite parts.

Design Data Verification

Engineering documentation brings visibility to the composite details during verification, including drop-off profiles, ply sequence order, and ply materials. Fibersim helps automate the creation of cross sections, annotations, and core samples that are updatable as changes occur, ensuring the design is accurately reflected. Fibersim core sampling capabilities provide deeper details, such as ply thickness changes, fiber deviation, balance, and symmetry, which are invaluable in ensuring product quality. Understanding laminate weight and cost is critical to making go/no-go decisions during verification. Fibersim instantly provides the laminate weight and cost, including post cure processes, to provide the most accurate information during review.

Detailed Design Definition

Whether you are designing a solid airfoil with Fibersim’s Volume Fill capability, using Zone-based design to produce nested plies in a large structural component, or leveraging Fibersim’s unique Multi-Ply approach to automate a ply-based design, Fibersim has the optimal design methodology for your part type. Once authored, this complete composite definition can be leveraged throughout the enterprise, from flat patterns and laser projected ply boundaries on the shop floor to 3D documentation for design reviews to accurate weights directly in Teamcenter.

Preliminary Design

Fibersim’s bi-directional Analysis Interface provides an automated exchange of stress requirements into a CAD digital twin. Even before detailing the part with design rules, preliminary weights and space claim solids can be derived from the zone definition. Once the final ply boundaries have been defined, the true fiber orientations can be sent back to stress to be re-analyzed with the as-manufactured definition.

Product Producibility Simulation

Fibersim’s producibility simulation is a production-proven capability to accurate flat patterns and true fiber orientations. With the complex curvature and advanced materials of modern composites, specified orientations cannot be assumed, and having a reliable simulation of the part producibility is critical to repeatable and high-performing parts. Fibersim can also provide a preliminary look at path planning challenges for automated deposition.

FiberSIM / FiberSIM

FiberSIM, a product of Siemens, is a software for the design and production of composite materials, especially composites. This software is one of the most well-known software in the design and production of various composites, which is widely used in industries such as aerospace, automotive, marine and renewable energy. With the unique tools and features that this software provides, you can draw all kinds of simple and complex designs and prepare standard, engineered, light and durable designs and bring them to the production stage. In addition, this software is the only software that supports all the engineering processes of composites and composite materials from initial design and creation of layers to simulation, documentation and production. It is also fully integrated with other engineering software such as CATIA, NX and Creo, which means it is possible to create a completely accurate and perfect digital composite product.

Key features of FiberSIM software

: – supporting all phases of composite design and manufacturing

– integrated with other engineering software such as CATIA

– automatic documentation of all design specifications and details

– simulation based on materials and production process to increase productivity

– defining limits and details Plan to save time and money

– automatically generate production data such as cutting patterns and layout of the laser system

Related products

engineering softwares

engineering softwares

engineering softwares

engineering softwares

engineering softwares

Oil and Gas

unlimited find

Optical software

Simulation

engineering softwares

Cad/Cam

engineering softwares

engineering softwares

engineering softwares

Cad/Cam

Mathematical

engineering softwares

engineering softwares

engineering softwares

Simulation

engineering softwares

scientific software

engineering softwares

engineering softwares

engineering softwares

Mining Industry

engineering softwares

Simulation

engineering softwares

Cad/Cam

engineering softwares

engineering softwares

Simulation

engineering softwares

Uncategorized

engineering softwares

chemistry software

engineering softwares

engineering softwares

Simulation

engineering softwares

engineering softwares

Geology

engineering softwares

engineering softwares