Hexagon Vero WorkNC 2025.2

€0.00

Hexagon Vero WorkNC 2025.2 crack license unlimited working.

Hexagon Vero WorkNC 2025.2 crack license unlimited working.

how to download Hexagon Vero WorkNC 2025.2 full crack working perpetual activation key.

WorkNC CAM software is the premier automatic CNC software for surface or solid models in mold, die and tooling businesses for 2 to 5-axis CNC programming, which perfect for surface or solid models in mould, die and tooling. WorkNCs multi-threaded processing takes advantage of multi-core computers giving blisteringly fast calculation and processing times. Preparation times are also reduced thanks to predefined machining sequences and batch mode toolpathcalculations.

We’re excited to present our latest WORKNC 2024.1 updated with the Hxgn Global Finishing feature that allows you to finish an entire part with one toolpath, enhancing surface quality by optimizing toolpath ordering and controlling tool wear. Make sure to watch the video to see how you can overcome the restrictions of the current “Combined Z-Level + Optim” toolpath.

Hexagon (NASDAQ OMX Stockholm: HEXA B) is a leading global provider of design, measurement and visualisation technologies. Hexagon has more than 14,000 employees in over 40 countries and net sales of about 2,400 MEUR.

Our products are used in a broad range of industries including surveying, power and energy, aerospace and defence, construction, safety and security, automotive and manufacturing. Vero Software, a part of Hexagon Manufacturing Intelligence’s Production Software business. Hexagon acquired Vero Software, a specialist in CAD/CAM software, in 2014 and has continued to expand and diversify its offering.

Owner: Hexagon

Product Name: Vero Software WorkNC

Supported Architectures: x64

Languages Supported: multilanguage

System Requirements: Windows *

Hexagon WorkNC 2024.1 | 2.48 Gb Update Hexagon Vero WorkNC 2025.2 4/9/2025

Hexagon Vero WorkNC 2025.2 Advanced CNC Machining

Hexagon Vero WorkNC is a powerful computer-aided manufacturing (CAM) software solution designed specifically for advanced CNC (Computer Numerical Control) machining. Recognized as a premier tool in the industry, WorkNC is widely used by moldmaking, die casting, aerospace, automotive, and precision engineering companies that require high levels of accuracy, surface quality, and efficiency in their machining processes.

WorkNC stands out for its ease of use, automation capabilities, and ability to generate highly reliable toolpaths. The software is designed to streamline the entire machining workflow, from roughing to finishing, while minimizing programming time and reducing machine tool wear.

Main strengths

Ease of use with automation

WorkNC is designed to reduce programming complexity. Its automatic toolpath generation allows users to generate optimal machining strategies without the need for deep expertise in CNC code. This reduces human error, shortens setup time, and allows less experienced operators to achieve professional results.

The superiority of 3D and 5-axis machining

3D Machining: WorkNC is built to create high-precision 3D toolpaths, ideal for molds, dies, and complex freeform geometries.

5-Axis Machining: The software’s advanced 5-axis strategies enable machining of complex surfaces and undercuts with minimal repositioning. Built-in collision detection and avoidance improves safety and efficiency.

Surface quality and accuracy

WorkNC is renowned for producing exceptionally smooth, polished surfaces immediately after leaving the machine, reducing the need for time-consuming polishing and reworking. This is crucial in industries such as mold making where precise details directly impact product quality.

High-speed machining (HSM)

The software includes optimized strategies for high-speed machining that allow for faster material removal while reducing tool wear and machine stress. This contributes to shorter cycle times and lower operating costs.

Key Features of Hexagon Vero WorkNC

1. Automatic tool path generation

- Automatic detection of material, workpiece and cutting conditions.

- Reliable tool paths generated with minimal manual input.

- Adaptive machining strategies to optimize cutting speed and feed.

2. 3-axis machining

- High-performance roughing, semi-finishing and finishing cycles.

- Advanced surface finishing for complex, free-form surfaces.

- Z-surface machining, smooth surface finishing and spiral finishing.

3. 5-axis machining

- Fully synchronized 5-axis strategies for complex parts.

- Collision detection and prevention for safe machining.

- Support for impellers, turbine blades and mold cavities.

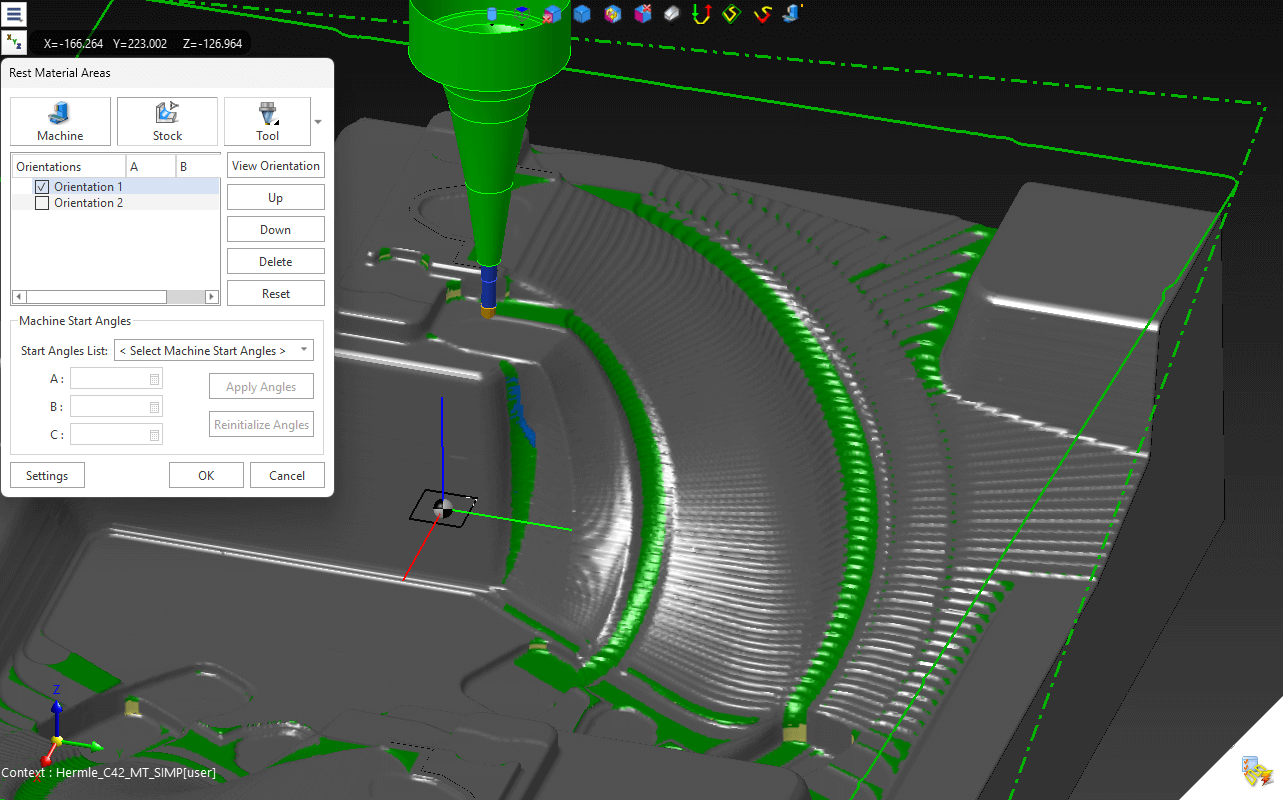

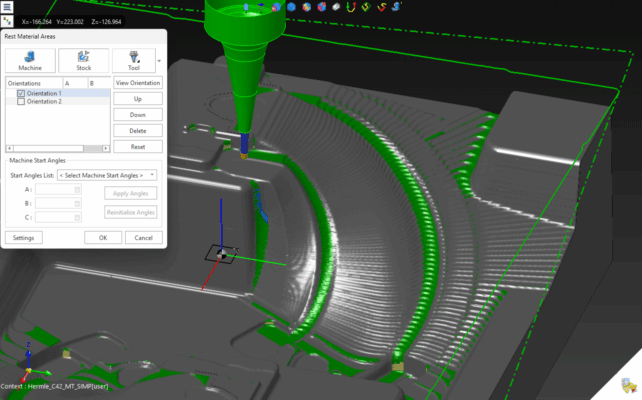

4. Machining at rest

- Automatically detects residual material from previous operations.

- It uses smaller tools for machining only when needed, reducing time.

- Efficient toolpath generation for tight areas and precise details.

5. Automation and ease of use

- Smart macros for repetitive tasks.

- Intuitive user interface designed for operators and programmers.

- Minimal learning curve with a focus on productivity.

6. High-performance roughing

- Advanced tool engagement control to protect cutting tools.

- Optimal tool path strategies to increase tool life.

- Shorter cycle times with dynamic roughing techniques.

7. Simulation and verification

- Realistic 3D simulation of machining operations.

- Collision detection for tools, holders and machine elements.

- Verification ensures safe and efficient machining before production.

8. Integrating mixed production

- Supports incremental + decremental processes.

- Ideal for repairing molds or creating complex parts with combination machines.

9. Tool Management

- Centralized database for tool libraries.

- Automatic tool selection based on geometry and material.

- Optimal cutting strategies for efficiency.

10. Customization and Scalability

- Modular structure with optional add-ons.

- Adaptable to small workshops or large industrial facilities.

- Integration with CAD systems for a seamless workflow.

Benefits for producers

- Reduced programming time: Automated functions reduce programming execution time and allow companies to respond to new tasks more quickly.

- Lower machining costs: Efficient tool paths reduce tool wear, machine time, and energy consumption.

- Improved part quality: Excellent surface finish reduces the need for manual polishing.

- Scalability: WorkNC is suitable for both small workshops and large-scale manufacturing facilities.

- Integration with CAD and PLM: Seamless data exchange with CAD systems and the Hexagon ecosystem ensures seamless workflow integration.

Conclusion

Hexagon Vero WorkNC is more than just CAM software – it’s a comprehensive CNC programming solution designed for accuracy, productivity and reliability. Its ability to automate toolpath generation, easily manage complex geometries and deliver world-class surface quality makes it the right choice for industries where efficiency and accuracy are non-negotiable.

With modular scalability, an intuitive user interface, and strong integration with CAD/CAM ecosystems, WorkNC gives manufacturers a competitive advantage, whether in advanced mold making, aerospace part machining, or automotive production. Combined with robust simulation and verification features, the software ensures that machining operations are safe, efficient, and cost-effective.

In short, Hexagon Vero WorkNC is a premium CNC software package that enables manufacturers to achieve high-quality results while reducing programming time and increasing overall productivity.

Hexagon Vero WorkNC is not just a CAM package, but a complete CNC machining solution. It is trusted worldwide because it combines automation, high accuracy, advanced toolpath strategies and multi-axis capabilities, helping manufacturers deliver complex, high-quality components faster and more cost-effectively

Related products

Dental Software

Uncategorized

Uncategorized

Mathematical

Geology

Uncategorized

unlimited find

Uncategorized

Uncategorized

Science Research

Uncategorized

engineering softwares

Oil and Gas

Science Research

Uncategorized

Science Research

engineering softwares

Uncategorized

Biomedical

Mining Industry

Uncategorized

Uncategorized

Simulation

Uncategorized

Uncategorized

unlimited find

Uncategorized

Geology

Uncategorized

Cad/Cam

chemistry software

Uncategorized

Mathematical

Mining Industry

Science Research

engineering softwares

Uncategorized

Uncategorized

Mathematical

Uncategorized

Simulation

Science Research

Cad/Cam

Uncategorized

Uncategorized