Romax DT 2025.1 crack license download Romax designer v2025

€0.00

Romax DT 2025.1 crack license download Romax designer v2025, Discover Romax 2025.1 for enhanced gear design, advanced analysis features, and streamlined workflows. Download now.

Romax DT 2025.1 crack license download Romax designer v2025 Romax DT 2025.1 Power Transmission Systems Analysis

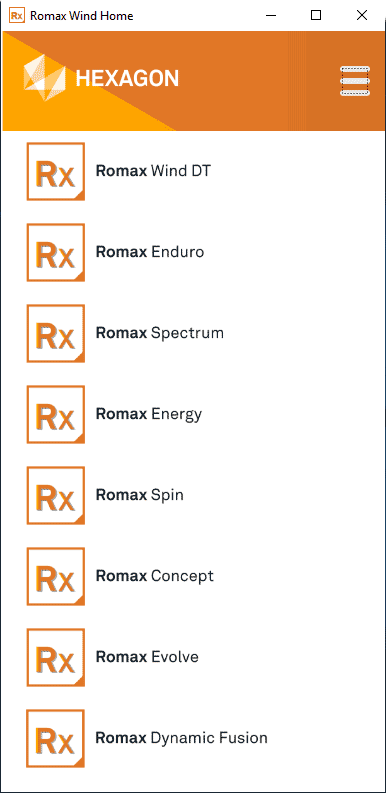

Hexagon is proud to announce the availability of Romax DT 2025.1, released as part of the full Romax software suite.

Romax

The most complete simulation platform for engineering the next generation of electro-mechanical drive systems

Embrace the future with Romax 2025.1

Discover Romax 2025.1 for enhanced gear design, advanced analysis features, and streamlined workflows. Download now.

The following article contains some overview information about the new features in Romax DT.

Customers can get more information on these features on the Nexus Documentation Center here.

If required please see this article for full instructions on how to gain access to this information on the Nexus Documentation Center.

Romax DT 2025 crack license Common Features

Gears

Cylindrical Gears – Support for Advanced tooth stiffness in static analysis and GBTE

The Advanced tooth stiffness model for loaded tooth contact analysis (LTCA) is now made available for use in Gearbox Transmission Error (GBTE) analysis and static analysis when ‘Include micro-geometry in static analysis’ is enabled (static analysis with micro-geometry).

The Advanced tooth stiffness model is the same 3D finite element-based model that was made generally available in 2023.1 for single mesh micro-geometry analysis.

Using the Advanced model in GBTE analysis allows for the highest fidelity analysis of helical gear tooth contact and calculation of transmission error (TE) and tooth stiffness for NVH analysis. The benefits of the 3D FEA-based coupled tooth bending model are combined with the system-wide approach to gear mesh stiffness and excitation calculation of the GBTE analysis. In addition to linear/transverse TE, the GBTE analysis is able to predict tilt/misalignment TE caused by the centre of pressure in the mesh shifting side to side during the tooth pass. This additional excitation can then be applied in NVH analysis.

Typical use cases include:

- GBTE analysis for the highest fidelity prediction of linear and tilt TE, and tooth mesh stiffness for NVH analysis

- Static analysis with micro-geometry for better prediction of misalignment for ratings

Some improvements and bug fixes for the advanced LTCA are included:

- Bug fix for mathematical solution of the Weber contact model

- A new setting in Global Preferences > File Save Options for choosing whether or not to save the gear tooth compliance data with the design. This allows trade off between disk space and tooth compliance calculation time.

- The tilt transmission error amplitude and phase of 1st, 2nd, and 3rd harmonics have been added to the tables in the NVH Analysis tab of GBTE Results worksheet.

- Speed-up of the tooth compliance calculation. For the Detailed Electric Powertrain example with default Advanced tooth stiffness model settings (16×8 nodes), an overall speed-up of about 40-60% was observed on a couple of different machines.

Note that the compliance calculation also includes building of the FE tooth model which takes roughly the same amount of time in 2025.1 as it did in 2024.1. Also note that compliance calculation is required only once and invalidated if the gear macro-geometry or material is changed. The running of micro-geometry or GBTE analysis is not affected.

Cylindrical Gears – Modification to gear mesh misalignment workflows and reporting

The mesh misalignment of spur and helical gears is usually expressed as a linear distance measured in the transverse direction in the plane of action. However the exact definition of the measurement is open to interpretation (e.g. in ISO 6336) which can cause confusion when comparing results and transferring misalignments between applications. For this release an alternative definition of mesh misalignment has been added to Romax which is aligned to the definition used by LDP and other simulation tools.

The reporting, naming, documentation and related workflows have also been made more consistent and clearer to the user and it is now possible to specify mesh misalignments for loose microgeometry cases using this alternative definition.

The definitions now supported by Romax are:

- Shaft misalignment– maximum deviation between the gear axes of the mating gears, measured in the transverse direction in the plane of action

- Previously this was the only result reported in Romax and it was referred to as gear mesh misalignment, or fbetaX, or simply misalignment.

- It remains available and depending on context may have slightly different names, but the word ‘shaft’ is always present

- Lead mismatch – maximum deviation between the tooth flanks of the mating gears, measured in the transverse direction in the plane of action

- This is a new result, which can be useful for determining lead micro-geometry modifications and for running third-party loaded tooth contact analysis (LTCA).

For spur gears both definitions give the same result. For helical gears the lead mismatch is larger than the shaft misalignment and it is a function of the shaft misalignment and the base helix angle.

Summary of changes to the user interface and the Help:

- The existing misalignment reports under Reports > Gears have been renamed and tweaked and a new report of lead mismatch is available for parallel gears.

- Both misalignment values are reported in the Micro-geometry Analysis Case Settings table in the micro-geometry worksheet.

- When specifying a loose micro-geometry analysis case, it is possible to choose between specification of shaft misalignment and lead mismatch. The value is automatically converted when switching between the two options.

- The relevant Parametric Study and Batch Running targets and results have been renamed, and lead mismatch has been added.

- The Default Lead Correction dialog has been modified to clarify that the misalignment used in it is the lead mismatch.

- The Rating case defaults dialog has been modified to clarify that when inputting mesh misalignment, the value is the shaft misalignment.

- The software Help has been updated to reflect the changes and provide detailed explanations of the definitions of gear mesh misalignment in Romax.

Modelling and Usability

Standard reports – Extended support for Summary Results Duty Cycles

Romax supports two duty cycle types: Full Results Duty Cycles (FRDCs) and Summary Results Duty Cycles (SRDCs). FRDCs are the default duty cycle type and store all results for all load cases in memory. For this reason, they are suitable for small to medium sized duty cycles where memory usage is not an issue. SRDCs are optional and are much more memory efficient, as they store the important duty cycle results alongside the detailed results for the last run load case only. SRDCs are therefore much better suited to large duty cycles with many load cases, where the focus is looking at the overall duty cycle results and it is acceptable to rerun any load case that requires detailed results.

Prior to 2025.1, only a limited set of standard reports were available for SRDCs. For 2025.1 The suite of Romax reports now have expanded support for SRDCs, and some reports have been redesigned for better usability. When using a model with SRDCs and having selected an SRDC to investigate, you may now view the following reports:

- Gear Mesh Misalignments – the summary table has been transposed and the detailed results have been moved to sub-pages; when using with a SRDC, the detailed results are available only for the last run load case.

- Gear Mesh Misalignments Summary – the summary table has been transposed; the report is identical for SRDCs and FRDCs.

- Contact Patch – the formatting is unchanged; when using this with a SRDC, results are available only for the last run load case.

- Bearing Complete Analysis – the formatting is unchanged; when using this with a SRDC, the summary results on the 1st and 2nd pages are fully available, but the detailed results on the 3rd page are available only for the last run load case.

- Housing Displacements – the formatting is unchanged; the report is identical for SRDCs and FRDCs.

- Gear Mesh Forces – the formatting is unchanged; the report is identical for SRDCs and FRDCs.

- Load Case Full Report (under System Level > Efficiency) – the formatting is unchanged; the report is available only for the last run load case.

- Clearance and Mounting – the formatting is unchanged; the report is identical for SRDCs and FRDCs.

- Gear Scuffing Calculations for Current Load Case – the formatting is unchanged; the report is available. only for the last run load case.

- Gear Micropitting Calculations for Current Load Case – the formatting is unchanged; the report is available only for the last run load case.

- Gear Film Thickness Results for Current Load Case – the formatting is unchanged; the report is available only for the last run load case.

Customised Reporting – New dataset for designed gear micro-geometry

When lead/helix slope modifications are applied as gear micro-geometry, this effectively changes the helix Customised Reporting has been enhanced to include a new dataset containing designed gear micro-geometry parameters for the default tooth. This allows micro-geometry design data to be included in custom reports alongside other gear data such as contact results.

The added parameters are in a new standard dataset named ‘Gear Micro Geometry’ and include the following:

- Lead crown/slope

- Involute barrelling/slope including between measurement diameters

- Linear/parabolic tip/root relief amounts and starts

- Linear/parabolic top/bottom end relief amounts and starts

- Change in bias at top/bottom of lead evaluation limit

- Position of zero bias on involute

- Top/bottom lead evaluation limit

- Tip/root involute evaluation limit

- Tip/root measurement roll angle

- Relief from tip/root measurement diameter

- Normal pressure angle plus profile slope

- Signed helix angle plus lead slope

Parametric Study & Batch Running Enhancements

The following enhancements have been added to Parametric Study and Batch Running:

- The parameter Working centre distance has been added as a target/result in Parametric Study and Batch Running. It is available for loading, concept and detailed spur/helical gears including mounted and unmounted gears and gear sets with multiple gear meshes.

- The parameter Effective mounting thickness has been added as a variable in Parametric Study and Batch Running. It is available for rolling bearings where this parameter has been overridden in the Rolling Bearing Arrangement window and can be found under the bearing and the relevant connection to the shaft or housing.

Nexus Compute Website Shortcut

We have added a button to the Romax UI to allow users to open the Nexus Compute web page in their default web browser. From here users can register and purchase credits used to run analysis jobs on cloud HPC.

For Romax users this could be to run an FE condensation in Nastran or an acoustic analysis in Actran where they don’t currently have a seat license or a machine with sufficient memory.

Romax Spin

Improved runtime and consistency of contact results for bearings with estimated advanced data

From the 2025.1 release, analyses of roller bearings with estimated advanced data, such as catalog bearings, now use the Basic contact model for all bearing results. For this case previously a mix of models was used.

Aligning all calculations improves consistency and runtime for bearings with estimated advanced data since the Basic model is faster. For analysis of bearings with fully defined advanced data in Romax Spin there is no change – the Advanced contact model continues to be used for both life and contact results, as in previous versions.

This update ensures faster and more consistent analysis of catalog and other bearings with estimated advanced data, while maintaining the detailed capabilities for bearings with fully defined advanced data.

The following table summarises the changes, which are highlighted in blue.

| ISO/TS 16281 life | Contact/subsurface stress, film thickness | Romax Advanced life | DIN ISO 281 sup. | |

| Estimated bearing advanced data | Basic – no change | Basic – new | Basic – new | Basic – new |

| Fully specified bearing data | Advanced – no change | Advanced – no change | Advanced – no change | Advanced – no change |

As shown in the table, this change also applies to obsolete life rating methods Romax Advanced, DIN ISO 281 sup. and Adjusted DIN ISO 281 sup. Previously, for bearings with estimated advanced data, these were based on the Advanced contact model, even though the ISO/TS 16281 results were based on the Basic contact model, which was another inconsistency that has been eliminated.

Minor UI changes:

- The Contact Stress Summary in Bearing Results now reports which line contact analysis type is used and this should always match the Calculation method used and reported for bearing life results.

- A minor update involves the addition of the life factor a1 in the table Advanced Life Modification Details present in the Bearing Results when viewing Romax Advanced life results.

For more background, the main difference between Basic and Advanced ISO/TS 16281 life is in the line contact model used for calculating the contact stress. However, even when ISO/TS 16281 Basic life was reported, in previous versions the contact results from the Basic model were not available to the user and instead the Advanced contact results were shown. This means there was a mismatch between the life results and the contact results in Romax Spin when analysing catalog bearings or custom bearings with estimated advanced details. In addition, the sophistication and extended runtime of the Advanced contact model are not justified and were wasted on bearings with estimated advanced data.

Related products

Geology

Uncategorized

Mathematical

engineering softwares

Mining Industry

Mathematical

Uncategorized

Uncategorized

Uncategorized

Mining Industry

Uncategorized

Uncategorized

Oil and Gas

Uncategorized

Uncategorized

Uncategorized

Uncategorized

unlimited find

scientific software

Uncategorized

unlimited find

Biomedical

Mathematical

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Science Research

Cad/Cam

Uncategorized

Uncategorized

Uncategorized

Science Research

Dental Software

Uncategorized

engineering softwares

unlimited find

Uncategorized

unlimited find

Uncategorized

Simulation

Simulation

Cad/Cam