TwinMesh 2025 CFD simulation

€0.00

TwinMesh 2025 CFD simulation crack license download unlimited working tested.

TwinMesh is a specialized pre-processing software used in Computational Fluid Dynamics (CFD) simulations, particularly designed for modeling and simulating positive displacement rotary machines

TwinMesh 2025 CFD simulation crack license download unlimited working tested.

TwinMesh is a specialized pre-processing software used in Computational Fluid Dynamics (CFD) simulations, particularly designed for modeling and simulating positive displacement rotary machines

Fast – Reliable – Efficient

A revolutionary meshing solution for reliable CFD analysis of rotary positive displacement machines

TwinMesh v2025

TwinMesh is a meshing software developed by CFX Berlin Software GmbH, Germany. It automatically generates hexahedral meshes for the computational fluid dynamics (CFD) simulation of the continuously changing fluid volumes of the working chambers of rotary positive displacement (PD) machines. The product was first time released in 2014.

TwinMesh supports floating licenses via LM-X license manager for 64-bit Windows and Linux systems.

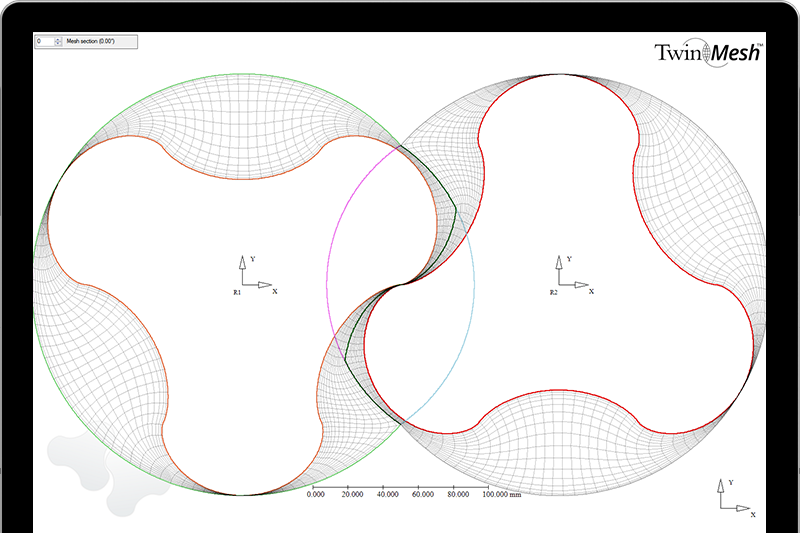

TwinMesh automatically generates high quality hexahedral grids for the moving parts of rotary positive displacement machines such as gear, lobe, gerotor and vane pumps or screw and scroll compressors.

TwinMesh is complementary to market leading CFD solvers like Simcenter STAR-CCM+ and Ansys CFD. It allows for reliable CFD analysis of pd machines using all physics available in these CFD software packages.

How does it work?

Easy Import

In TwinMesh the import of rotor and casing contours is realised as a 2D cross section via IGES format or CSV text files. Casing curves can also be generated in TwinMesh. All these contours can be easily scaled in order to modify e.g. clearance dimensions between rotors and casing. Rotor positions can also be adapted after the import defining axis-positions for the directions X and Y. If required, TwinMesh then automatically generates interfaces between the rotor meshes.

Auto Generation of Hexahedral Meshes

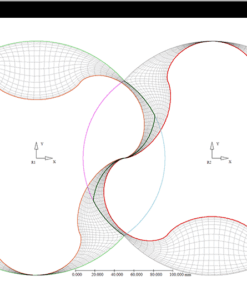

In the next step TwinMesh generates hexahedral meshes for all user defined rotation angles. Using special smoothing algorithms the software takes care of a sufficient gap resolution, smooth changes between small gaps and larger chambers and an homogeneous element distribution.

Easy Export

After a final check of the numerical quality the grids can be exported as 3D model or as 2D model. The export data of TwinMesh contains all required meshes for a transient flow simulation as well as the required routines for the automatic mesh import while running the simulation in Simcenter STAR-CCM+ or Ansys CFX. Also, a ready-to-run simulation template is exported by TwinMesh, which enables an immediate start of a flow analysis with the CFD solver. Using the structured grids from TwinMesh singlephase and multiphase CFD and CHT simulations can be performed.

Implementation of mesh movement in TwinMesh v2025

Rotating positive displacement machines consist of fluid volumes (called chambers) that are connected by gaps. The chambers transport the fluid while the gaps lead to leakage flow (losses). The position and the shape of the chambers and gaps change with time, depending on the position of the rotor(s). For the CFD simulation of the fluid flow with the finite volume method, this change in position and shape has to be accounted for in the meshes that describe and divide the fluid regions.

TwinMesh is a software which pre-generates these numerical meshes of the chambers and gaps for each rotational position and exports the node positions in a set of files. By using structured meshes (typically hexahedral block-structured O-grid meshes), TwinMesh ensures that the topology of the meshes keeps the same for each rotational position, i.e. the node numbers and node connectivities stay the same.

The CFD solver, then reads in these mesh files during run-time with special routines provided by TwinMesh and uses them for the deforming mesh approach. The location of each mesh node is updated at the start of each time step, and the CFD solver considers the movement of the mesh nodes as an additional term in the Navier-Stokes equations and further partial differential equations, e.g. for turbulence.

Since the topology of the meshes keeps the same, no interpolation of the solution values is necessary during the transient simulation unlike for the remeshing approach. This reduces the numerical errors significantly and decreases simulation time.

TwinMesh 2025 para simulación CFD: Visión general y aplicaciones

TwinMesh es un software especializado de preprocesamiento utilizado en simulaciones de Dinámica de Fluidos Computacional (CFD) , diseñado específicamente para modelar y simular máquinas rotativas de desplazamiento positivo , tales como:

- Compresores de tornillo gemelo

- Sopladores Roots

- Bombas de engranaje

- Motores Wankel

- Compresores scroll

Desarrollado por CSC – Computational Sciences GmbH , TwinMesh automatiza la creación de mallas hexaédricas de alta calidad para geometrías rotativas complejas con holguras muy pequeñas. La versión 2025 probablemente incluya mejoras en automatización, precisión e integración con solvers CFD líderes como ANSYS Fluent, CFX, OpenFOAM y CONVERGE.

Principales características de TwinMesh 2025

- Generación automática de malla

- Malla estructurada hexaédrica completamente automatizada para máquinas con rotores gemelos.

- Maneja holguras pequeñas y tolerancias ajustadas con alta precisión.

- Importación de geometría

- Soporta formatos CAD como IGES, STEP y Parasolid.

- Permite importar perfiles de rotor desde datos medidos o ecuaciones analíticas.

- Configuraciones multi-etapa y multi-lóbulo

- Soporta simulación de compresores y bombas multietapa con distintas configuraciones de lóbulos.

- Configuración de movimiento de malla dinámica

- Funcionalidad integrada para definir movimiento rotativo en zonas móviles.

- Facilita simulaciones transitorias con precisión temporal.

- Integración con solvers CFD

- Exportación directa a plataformas CFD populares:

- ANSYS Fluent / CFX

- OpenFOAM

- CONVERGE

- STAR-CCM+

- Incluye plantillas y condiciones de contorno específicas para cada solver.

- Exportación directa a plataformas CFD populares:

- Modelado térmico y de holguras de fuga

- Modelado mejorado de expansión térmica para predicción precisa de holguras de fuga bajo condiciones operativas.

- Interfaz de usuario mejorada

- Flujo de trabajo simplificado con mejores herramientas de visualización y detección de errores.

- Soporte para procesamiento paralelo

- Generación de malla más rápida mediante el uso de CPUs multinúcleo.

Flujo de trabajo típico usando TwinMesh 2025

- Importar geometría del rotor

- Cargar archivos CAD o definir perfiles de rotor analíticamente.

- Definir dominio y holguras

- Especificar los límites del alojamiento y las holguras entre rotor-rotor y rotor-alojamiento.

- Generar malla

- Usar el motor de mallado automático de TwinMesh para crear una malla hexaédrica estructurada.

- Configurar movimiento y zonas

- Definir zonas rotativas y parámetros de paso de tiempo para análisis transitorio.

- Exportar archivos del caso

- Exportar la malla y la configuración al solver CFD objetivo.

- Ejecutar simulación CFD

- Realizar análisis de flujo, presión, temperatura y eficiencia.

- Postprocesamiento

- Analizar resultados usando postprocesadores CFD (por ejemplo, ANSYS CFD-Post, ParaView).

Related products

Oil and Gas

Uncategorized

Uncategorized

Uncategorized

Mathematical

Uncategorized

Mining Industry

Uncategorized

Uncategorized

Dental Software

Uncategorized

Mathematical

Uncategorized

Uncategorized

Geology

Uncategorized

Uncategorized

Uncategorized

Cad/Cam

Mathematical

engineering softwares

unlimited find

Biomedical

Uncategorized

Uncategorized

Geology

chemistry software

Science Research

Uncategorized

unlimited find

Science Research

Uncategorized

unlimited find

Science Research

Cad/Cam

Uncategorized

scientific software

unlimited find

Science Research

Uncategorized

engineering softwares

Uncategorized

Uncategorized