UcamX v2024.06 PCB design UcamX crack license

€0.00

UcamX,UcamX 2024 crack license download, torrent download UcamX 2024 crack license download, PCB manufacturing UcamX 2024 crack.

UcamX v2024.06 PCB design full crack license working tested.

UcamX 2024 crack license download,PCB manufacturing UcamX crack key.

Ucamco, a leading developer of software, photoplotting & direct imaging systems for the PCB industry, has launched UcamX Assembly Seat, a powerful addition to its CAM platform that bridges the gap between bare board production & assembly.

Before any electronic product reaches its final customer, it will have gone through multiple processes carried out by a series of independent specialist manufacturers who rarely communicate directly with each other.

For the most part, this works – UcamX 2024 crack but it can be a problem for assembly companies who must put bare boards and components together. They require detailed information about both elements in order to make valid decisions about how to place components, and whether the design constraints are in line with their own manufacturing capabilities and specifications.

Intelligent integrated solutions that combine data about bare boards and components are scarce or come at a premium, so many companies are using ad-hoc systems that are neither streamlined nor efficient.

UcamX 2024 crack With a decades-long commitment to developing leading-edge integrated production software that truly responds to, and grows with, the needs of the PCB manufacturing industry, Ucamco makes it a priority to listen to its customers and work closely with them. So when it was asked for help in improving assembly front-end processes, it stepped up willingly, as Ucamco’s Adam Newington explains: “What was needed was an easy way for assembly companies to understand the PCB, identify the components and placement requirements, and see and analyse board and component characteristics”.

All fairly straightforward information that should normally be provided by the design company but is not always forthcoming. As it happens, board designers generally output this information in Gerber and/or ODB files, together with the bare board data that PCB manufacturers need.

It’s a data format that UcamX handles every day, all over the world, so it was a natural enough step to extend the platform to encompass assembly-specific data management. UcamX Assembly Seat identifies the assembly data and reads it into a job database, putting it into an easily understandable visual format that can be interrogated, zoomed in on, collated and analysed to clarify quickly and easily exactly what the assembly process requires, while annular ring and solder pad land sizes and clearances can be analysed to see how they impact assembly.

UcamX Assembly Seat allows interrogation of components singly and by type, reference designator information or part name, PIN numbers and reference net names. Components, connections and net designators can be traced back to the designer’s original schematic, and BOMs and production documents can easily be generated. And there is potential for a whole lot more functionality.

Ucam has been facilitating front-end PCB manufacturing processes for decades. Now, with UcamX Assembly Seat, this powerful front-end electronics manufacturing solution takes a momentous first step across the PCB-assembly bridge, supporting assembly companies with intelligent, integrated functionality, all delivered with Ucamco’s trademark ease-of-use and simplicity.

UcamX v2024.06 PCB design UcamX crack license UcamX 2024 crack

Integration into any environment

We provide our customers with all interfaces, upstream to CAD/DFM, downstream to manufacturing and quality control. UCAMX PRO+ outputs fully-automated machine-optimized tooling for all industry-standard electrical testers and AOI systems, photo plotters, drilling and routing equipment and direct imagers. Product parameters can easily be uploaded into corporate production management databases, or in various formats for other CAD/CAM systems.

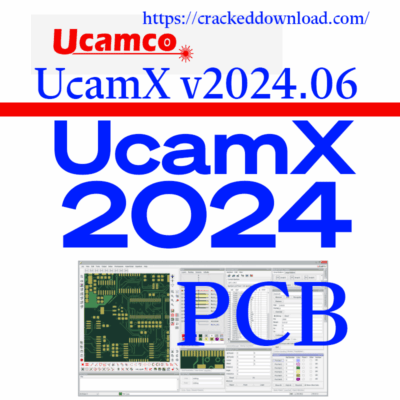

Parallel Processing

At the heart of UCAMX PRO+ are its 64 bit core engine and a smart feature called Parallel Processing (PP). They are the key to the software’s astonishing performance. The 64 bit core – which we were the first to offer over 10 years ago – addresses more computer memory and allows high layer-count jobs or massive data volumes to process without a hitch. In the Parallel Processing concept, highly efficient algorithms split up CPU-intensive CAM tasks between various CPUs of a multicore workstation and complete within a fraction of the time standard CAM software packages would need. The more CPUs, the faster the software.

High-level automation without limits

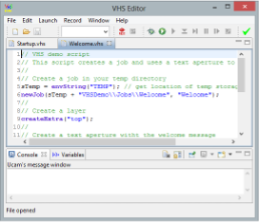

UcamX Hypertool scripting delivers in-depth custom automation without limits. Unlike batch-sequencers, HyperTools give you access to full core CAM functionality. Simplify and accelerate your process automation. Write new CAM routines to automate your new technologies or to integrate CAM deeply into your business systems. The Java™ carrier means that HyperTools are structured, robust and reliable, fully integrated into the UCAMX PRO+ GUI.

UcamX Visual HyperScript (VHS) scripting delivers operator level automation without limits. Record repetitive tasks or write new CAM routines to automate your CAM flow or to integrate CAM deeply into your business systems. The VHS function library contains more than 1000 commands.

Dedicated CAM functionality for all PCB technologies:

single sided, double sided, flex, flex-rigid, HDI, IC substrates

Yield Enhancing Layout Optimizer

YELO is a feature that automatically adjusts PCB layout to improve manufacturability. It significantly improves board layouts within minutes, cuts back your CAM cycle time by up to 30%, achieves superior production yields, delivers more reliable PCBs and slashes production cost on every batch.

Related products

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Dental Software

Uncategorized

Simulation

Cad/Cam

Biomedical

Uncategorized

Geology

Science Research

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Mathematical

Mathematical

Uncategorized

Uncategorized

Uncategorized

Science Research

Mining Industry

chemistry software

unlimited find

Geology

Science Research

engineering softwares

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Cad/Cam

Uncategorized

Mining Industry

unlimited find

Simulation

Uncategorized