Luceda 2025 Luceda Photonics IPKISS Design Suite 2025

€0.00

Luceda 2025,

Luceda Photonics IPKISS Design Suite 2025.12 crack license download

Luceda Photonics IPKISS Design Suite is an industrial-grade software platform for the design, simulation, and optimization of photonic integrated circuits (PICs) and optical components. The suite is widely used in fields such as optical communications, data centers, sensing, telecommunications, and semiconductor photonics manufacturing

Luceda Photonics IPKISS Design Suite 2025.12 crack license download

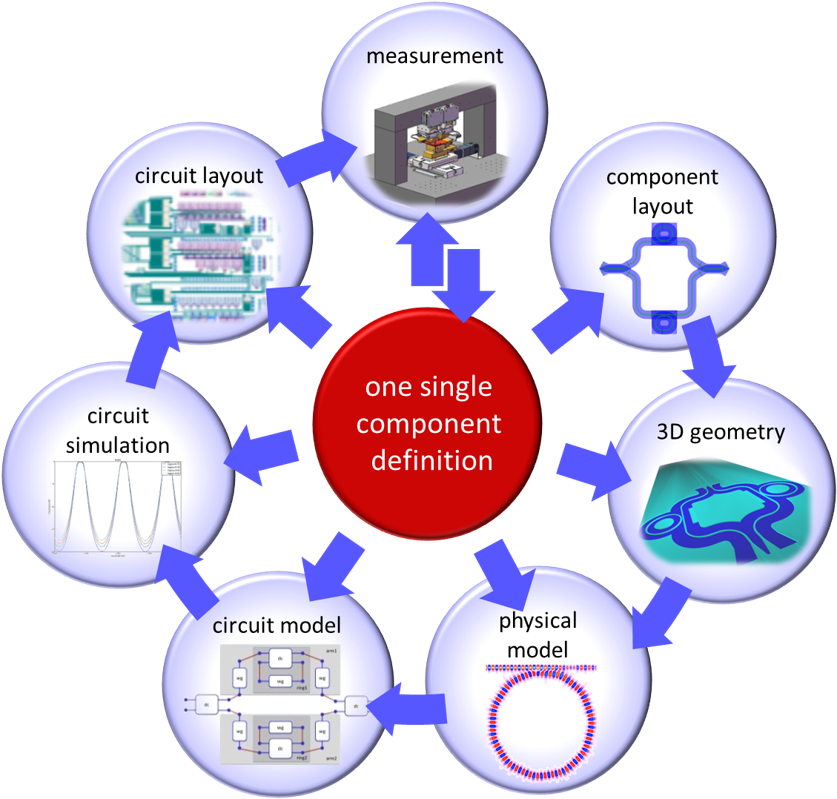

Photonic design happens at many different levels. A lot of the component design is still done using detailed electromagnetic simulations, tailoring geometries to a very detailed level. At the same time, circuit design requires abstraction at a much higher level.

Traditionally, these different steps in the design flow require very different tools, while at the heart they require the same component definition: at the end of your design you want the correct components to be placed on the mask for fabrication. IPKISS integrates the different aspects of photonic design into one framework, where you can define your component once as a parametric cell (PCell) and then use it throughout your design process:

- performing electromagnetic simulations,

- defining circuit models,

- connecting devices into a circuit,

- running circuit simulations,

- verify functionality (post-layout circuit simulation) and connectivity (IPKISS Canvas),

- automate the testing of your devices at all stages of the design cycle,

- generate the mask layout that will be sent to the fab,

- and finally even process the testing of the fabricated devices.

Because the same component definition is used in the entire flow, design errors are significantly reduced. Also, the level of automation that can be achieved with this flow can enable more efficient and error-proof design flows.

Designing a Photonic Integrated Circuit: Best Practices for Simulation & Layout

Introduction to Photonic Integrated Circuits (PIC)

For photonic integrated circuit (PIC) chip designers, it is important to be aware of the interoperability of simulation tools. Simulations may be the key to cutting-edge devices, but the capability to translate designs from simulation software into error-free, foundry-compatible blueprint files is also crucial to actualize the product.

The blueprint format, often referred to as the layout, has strict rule sets that vary between foundries. Although it is feasible to manually draw a layout, it can quickly become a Herculean task as photonic integrated circuits become more complex.

Hundreds of thousands of devices can fit within the average PIC chip. Thus, it is often unreasonable to draw and validate the layout manually.

IPKISS comes with several design kits already included, so you can start designing today! There are a range of open source Process Design Kits (PDKs) as well as SiFab, a stand-alone Luceda PDK that imitates a real silicon foundry. It contains a complete technology tree, as well as many common components such as waveguides, modulators, crossings and grating couplers. You can use to start learning how to design in IPKISS, or as a starting point to develop your own components or PDK.

Python Scripting

At the core of IPKISS is a powerful Python scripting framework. We opted for a scripting layer because it poses the minimum of constraints. The Python language is easy to read, is an accepted industry-standard, and comes with a rich ecosystem of scientific and engineering packages. Moreover, it makes IPKISS an open environment, where it is possible to integrate different design and simulation tools (even from other tool vendors) into your design flow. Python scripting is at the core of many PIC design activities: building parametric cells (PCells) and design IP, launching device simulations, generating full PIC layouts, running circuit simulations, verifying the correctness of your designs and so on.

Graphical assistance using IPKISS Canvas

In parallel with the Python code, users can also use IPKISS Canvas, a Graphical User Interface (GUI) that acts as a copilot to your PIC design activities. IPKISS Canvas assists you in capturing schematics, generating Python code, verifying designs and so on. The code generation reduces the barrier to entry for those not yet familiar with the platform, and acts as a starting point for further Python coding. IPKISS also has powerful connection extraction routines (both optical + electrical) that allow to verify the connectivity and correctness of your layouts in Canvas, prior to tape-out.

Luceda Photonics IPKISS Design Suite is an industrial-grade software platform for the design, simulation, and optimization of photonic integrated circuits (PICs) and optical components. The suite is widely used in fields such as optical communications, data centers, sensing, telecommunications, and semiconductor photonics manufacturing

The suite provides a unified environment that bridges the gap between theoretical photonic design and real-world fabrication. Instead of relying on manual design iterations and trial-and-error experiments, IPKISS offers a structured, automated, and physics-aware workflow that improves accuracy, efficiency, and manufacturability.

By combining layout design, optical simulation, performance analysis, and manufacturing-ready output in a single platform, IPKISS enables engineers to develop photonic devices that are not only functionally correct but also compatible with industrial manufacturing processes.

Key Features and Design Philosophy of Luceda Photonics IPKISS Design Suite

Luceda Photonics’ IPKISS is built on a workflow-based design methodology, meaning that each stage of the photonics development cycle is interconnected:

- Conceptual design → Definition of optical function and structure

- Component and circuit layout → Creating accurate waveguide geometries

- Optical simulation and validation → Predicting light behavior

- Optimization and sensitivity analysis → performance improvement

- Manufacturing Conformity Check → Ensuring manufacturability

- Export to manufacturing formats → Prepare files for foundries

This approach minimizes risk, reduces development time, and improves first-run success.

Purpose of Luceda Photonics IPKISS Design Suite

The main objectives of the IPKISS design suite are:

Providing an integrated platform for photonics design and simulation

- Replace inefficient manual design methods with automated workflows

- Bridging the gap between design and manufacturing

- Reduce development time and cost

- Improve design reliability and production success rates

- Possibility of developing industrial photonic chips on a large scale

This suite serves as a decision-making tool for engineering teams working on integrated photonics projects.

Full description of features

1. Design of waveguide layout and components

IPKISS provides a powerful layout environment for designing photonic structures, including:

- Straight and curved waveguides

- Dividers and combiners

- Y-branches and directional couplings

- Ring resonators and microresonators

- Mach-Zehnder interferometers (MZI)

- Optical modulators and detectors

- Cone and mode transducers

Designers can define components parametrically, meaning dimensions and properties can be adjusted dynamically without the need for manual redrawing.

2. Light propagation simulation

This suite includes simulation tools that model how light travels through photonic structures. This enables the following:

- Optical loss analysis

- Reflection and scattering behavior

- Signal transmission efficiency

- Interaction between different waveguide structures

These simulations help predict the performance of the device in the real world before manufacturing.

3. Optical state analysis

IPKISS can calculate and visualize the following:

- Optical modes inside waveguides

- Effective refractive index

- Optical field distribution

- Limiting mode and leakage

This is very important for designing photonic components with low loss and high efficiency.

4. Process Design Kit (PDK) and Foundry Support

Luceda Photonics integrates directly with foundry process design kits (PDKs) and ensures that:

- Designs comply with construction constraints

- Minimum feature size is respected.

- Waveguide dimensions match production capabilities

- Layer mappings are aligned with manufacturing processes.

This reduces the chance of construction failure due to design inconsistencies.

5. Parametric sensitivity analysis

This feature allows engineers to:

- Changing geometric parameters (width, length, curvature, etc.)

- Adjusting material properties (refractive index, absorption, etc.)

- See how these changes affect optical performance.

This is especially useful for robustness testing and efficiency optimization.

6. Performance optimization tools

IPKISS includes automated optimization algorithms that can:

- Minimizing optical loss

- Maximizing signal transmission

- Optimization of resonance frequencies in ring resonators

- Improved compatibility between components

This reduces manual tuning and increases development speed.

7. Multi-component interaction simulation

For complex photonic circuits, IPKISS can analyze the following:

- How multiple optical components interact in a system

- Frequency domain behavior

- Time domain signal propagation

- Interference between adjacent waveguides

This is essential for designing large-scale photonic chips.

8. Ready-to-build output

IPKISS supports industry standard file formats, including:

- GDSII for mask production

- OSP and other build-compatible outputs

- This allows for a seamless transition from design to production.

9. Advanced visualization and drawing

This software offers rich visualization tools for:

- Optical field distribution

- Transmission spectra

- Loss and reflection diagrams

- Mode profiles

These visual tools help engineers better interpret simulation results.

10. Thermal-optical analysis

Since temperature affects photonic behavior, IPKISS allows users to:

- Simulating thermal effects on the refractive index

- Study of wavelength changes due to temperature

- Adaptation of designs to real-world operational conditions

This is especially important for data centers and telecommunications applications where temperature changes occur.

11. Integration with other engineering tools

IPKISS can be integrated with:

- SPICE for joint electrical-photonic simulation

- Electromagnetic (EM) solvers

- Electronic Design Automation (EDA) Tools

- This enables multidisciplinary design workflows.

Conclusion

Luceda Photonics IPKISS Design Suite is a major advancement in photonics engineering software. It revolutionizes the way photonics devices are developed by integrating layout design, optical simulation, optimization, and fabrication preparation into a single environment. Its ability to accurately model light behavior, ensure casting compatibility, and automatically optimize performance makes it an essential tool for industries working with photonic integrated circuits.

Ultimately, IPKISS enables engineers to move from concept to manufacturable photonic systems with greater confidence, efficiency, and accuracy

Related products

Uncategorized

Geology

Science Research

Dental Software

unlimited find

Science Research

Uncategorized

Uncategorized

Uncategorized

Mathematical

Uncategorized

chemistry software

Science Research

Uncategorized

Uncategorized

Uncategorized

Cad/Cam

Science Research

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Uncategorized

Oil and Gas

Simulation

engineering softwares

Geology

Uncategorized

Uncategorized

unlimited find

Simulation

engineering softwares

Mining Industry

Geology

Uncategorized

Mathematical

Uncategorized

Science Research

Uncategorized

scientific software

Uncategorized

Uncategorized

Uncategorized

engineering softwares

Cad/Cam

Uncategorized